I did get a Confirmation for the press just not the accessories.

69274 I refreshed 11 times before it finally allowed me to.

I placed my order with the PRI show code.

It didn’t ask what options we wanted… Now I’m concerned.

options did not come up till later. Look under the Titan threads there is one that shows the options

My concern is how i add the options to my order.

Go ahead and send an email to support@langmuirsystems.com, Amanda or Mia will help you get the add-ons in the order!

Send an email to Amanda at Langmuir, and she will handle it.

support@langmuirsystems.com

when I sent mine it went to Fredrick not Amanda or Mia

Knick, I’m sure we will get first dibs.

I missed the window for the early show orders. Order #69259

#69454 and that was about 3min after

Order #67526, ordered during PRI.

You dawg you!!!

This is a funny thread. Good luck to you all, may the press be with you.

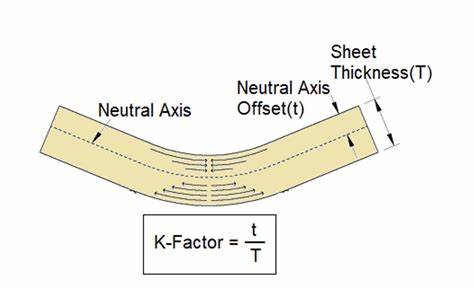

I see a lot of new users learning about K-factors because 8” + 2” bend don’t equal 10”. I’m not saying this to be funny or jerk. Saying this to help you learn how to design in a software with this ability to get full capabilities of your new machine if you plan on pairing your plasma cutting with bender.

I have #67525

Thanks for posting this. I have been more of a carpenter but have been having a local place cut and bend my sheet metal (hopefully for not much longer ![]() ). I’m reading through some articles on k factor to wrap my head around how it works. Looking at your formula above, wouldn’t the k factor always be 0.5 if you are dividing half the sheets thickness by the full thickness?

). I’m reading through some articles on k factor to wrap my head around how it works. Looking at your formula above, wouldn’t the k factor always be 0.5 if you are dividing half the sheets thickness by the full thickness?

Nah, because stretch happens and it’s different for every radius and material type. Elongation numbers start to matter, or you could just test bend, measure, and update your tables with the results rather than guesses. Even then things will change a little from one heat lot to the next, but if you start with good data you’ll be a lot closer to nominal than using generic numbers. Then just updating your springback will keep you in tolerance for most parts that aren’t super duper precise.

Fusion uses K-factor of 0.44. I did a really quick video if you plan on cutting and bending. I would suggest starting to play with software with sheet metal.

Wicked!! Thanks man ya I use fusion as my main cad software, haven’t done much sheet metal in there yet, but have a decent idea. I’ll go watch that video, I’m sure it will help immensely. Thanks!!!