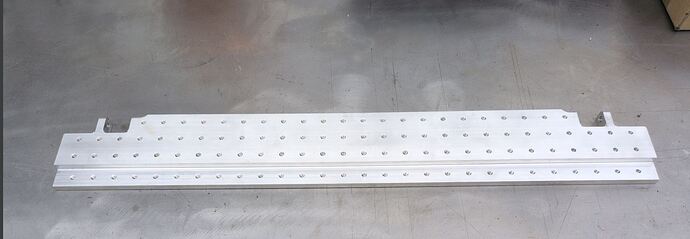

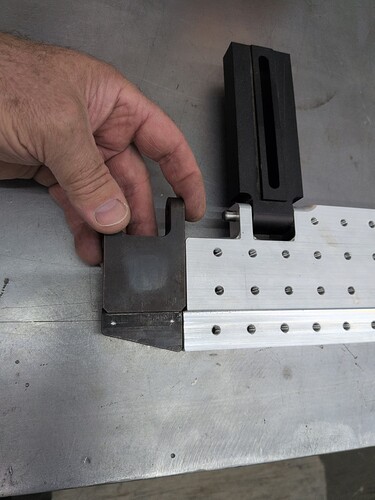

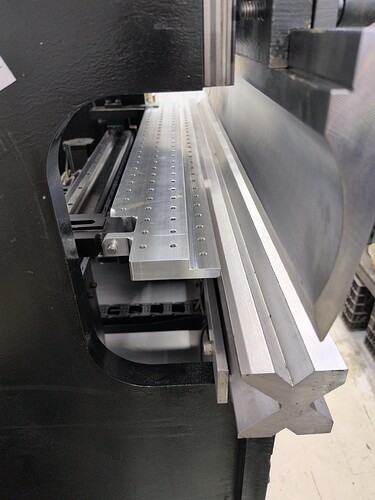

I perform a lot of mitered bends to manufacture these parts and quickly got tired of relocating the finger stops for each bend. My solution is a one piece BG . Same dimensions as the factory fingers, so all of the bend programs crossover without issue. 1/4-20 threaded holes with 1” spacing for attachments, 45 bend legs, odd angles, edge stops or odd part fixturing. I’ll probably print up a collection of attachments that can be bolted on, or simply thread in a series of allen head bolts for edge stops. 6061 was the choice for dimensional stability as I think cold rolled steel would warp when the top edge was milled off. It works well well for station bending multi bend parts. If anyone is interested, slide into my DM’s ![]()

Nice solution for multi-station bending! I’m not doing anything high volume enough to justify it, but I’m sure there will be guys who are.

Just a thought in case you find flatness to be an issue, you could buy 6061 jig plate and finish machine the profile and add the holes and end up with a pretty flat end product for anyone who’s got more money than sense.

thanks MrHaNkBoT! I figured 6061 bar would be within .010 flatness which is more than close enough for this purpose. I bought a piece 3/4” CR bar, but haven’t machined it yet - figured it would pull one direction after milling the stress out of it. I tried to drill and tap the stock fingers to bolt on a full width face, but they are tool steel hard as glass. carbide drill barely nicked it - instead of annealing i figured it would be easier to just make a new one that meets my needs. I’ve only bent 60 or so parts thus far, but never having to reach back and adjust the fingers ever again will save me countless hours ![]()

@custommetalmke makes replacement flat faced fingers that have tapped holes in them that combined with a flat bar drilled and tapped would get you most of the function, with some extra flexibility to make the bars/stations any size in case clearance is needed for a part to swing. I like supporting guys making something useful, especially if it’ll save me a couple days wasted recreating the wheel, so I bought one of his complete kits in steel.

yes, metalmke and ratha both made custom fingers for sale- both are well designed and manufactured products. I was going to do the bolt on, but i have a cnc mill so just as easy to take it a step further and get the grid pattern of holes for fixturing all in one plate. no more reaching in to adjust fingers in my tight shop space was the added goal.

I hate dusting off my mill to do that kind of work. If I had it rolled into my work flow better I might have been tempted, but machining is usually something I do in the pursuit of something else I’m making, not the primary hobby. Hopefully you didn’t think I was implying anything negative at all about your backgauge, just letting anyone else reading the thread know there are some other designs out there too.

Keep up the good work!

I had an long aluminum flat bar vise grip clamped on the stock fingers for weeks - it worked well to get my prototype station bends to the customer quickly, then it just sort of evolved from there. I’m not so much into the sales part of it - and so few people have these machines in the first place, most probably without the backgauge lol, then a large % of those that are even on this forum or who make posts - most are just trying to sort out the problems and get their machines fixed and running. I was just throwing it out there - but if someone wanted one, making the 2nd one is much much easier than the first lol