I am cutting 2 inch text stardust stencil since plane stencil gave me poor results.

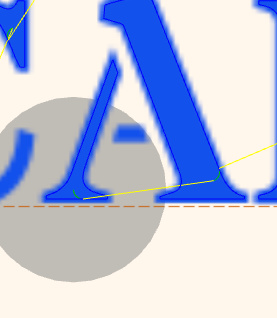

So I have read all the discussion on this error and have tried every combo of Knurf .01 to .08 and 60 to 95 degrees an all the combos. I am getting this error and the currently the part missing is the line in the (-) A. I have had this issue many times with text. Any help would be great.File with error

You may have to use no lead in angle or lead in distance. I have had this issue with some smaller cuts.

Thanks but that didn’t work.

Did you ever figure out how to fix this? I am having the same problem with anything I do that seems to have anything for detail

No and it has been a real annoyance. I put it on both the form and sent it technical support. I’ve heard nothing but the recommendation you might see above that did not work.

If the feature size is narrower than the kerf width, then the toolpath will not be able to fit, even without lead-in. Are any portions of the loops narrower than the kerf width?

I sent you the link to the actual drawing it’s only the dash in the capital A in either of the stencil fonts I’m using. I moved the letters all the way up to 1.9 inches. I have had this problem many times when doing letters. https://a360.co/2QA5Kjf

I have tried 3 diffren fonts and maniupulaed the leadin and degrees. I also sent to support

I am really frustrated with this issue. I have now drawn a set of cut lines to repalce to the 1 little part of the A missing.

Manually adjusting fonts so that they are cuttable is unfortunately a negative side effect of the plasma cutting process since the kerf width is fairly wide.

Agree - it’s easy to draw something that can’t be cut. The same is true on CNC routers & lasers. It’s just the size of the smallest cut that changes because the kerf is different on each.

I have to adjust my designs as I move from one device to another. You also need to be careful that the resulting piece isn’t too thin or narrow to be practical.

Try reducing the piercing clearance as well but there are a couple that are linked if you don’t adjust one first you can adjust the other.

By changing font and the size of the font I have finally fixed my letter cutting issue solved. It also matters the order that you cut. It’s a learning process that I think I’m over the hump.

I had this problem as well, it was frustrating but I eventually got it to cut. I had to go through about 6-10 times in the cam setup selecting the order that everything was cut. Sometimes it would cut a letter but the next it wouldn’t, so I kept jogging around between letters until it would cut all of them. When it finally would I felt like I won the lottery.

Well i had the same issue with a 7" part on fusion and what I found out I had to chanfer the end or make a readius in order for it to go trough so basically try not to leave corners on the part and it has seem to work fairly good with me