Wonder if the LVDT sensors are a bit out of adjustment but It seems they should zero at top of stroke so likely no adjustments. A UNIX system has a terminal mode that I have seen used on a underwater laser system we have used in my nuclear service work. Maybe that is a tool to be looked into? K

Computer code is not my area of knowledge at all - I was asking some of the others here how difficult it would be to change the code to get rid of the double tap pedal first, then ALL of the “you are doing this - click ok” prompts that neuter this machine. A signal interrupter via an Arduino wired in the pedal line i think could solve the double tap problem, but all of the nannies in the code is another animal to tackle. As far as the oil in the electrical cabinet, yes - my first thought was when, not if ~oil goes everywhere, it’s going to be very bad. Mineral oil is the only oil i know of that is compatible with electronics and computers - entire desktop boards, CPU’s, drivers etc can literately be submersed in mineral oil without issue - I have seen gamers put their computer systems in fish tanks and 5 gallons of mineral oil for superior cooling. The very first think I did not install the jog arm extensions, never even put them on the machine - i knew that would be a headache before I even got the machine delivered - here was my solution JOG ARM aka JarJar Binks FIX - #10 by AUminer AND Safety Override - T25 Press Brake - #7 by AUminer

The main changes involved using barbed hose connectors, and adding more holes to the lid for the lines to connect to.

In terms of a warranty upgrade, it really is not worth the effort it would take to install the replacement. You would need to take out your tank, strip the lid of silicone, disassemble it, clean up the silicone more. Replace the lid with the new lid and parts, then apply fresh silicone being very careful not of it enters the tank. Then reassemble everything. A lot of work for pretty little payoff when you have easier revisions you could do like just rerouting the pressure relief return lines outside of the machine.

The sealant you use….does not adhere to or stick to the flimsy and flexible vacu formed plastic tank…at all, as in ZERO. The fact that langmuir shipped out machines with plastic tanks and 3/16” gaps under the lids is beyond egregious, it’s downright infuriating.

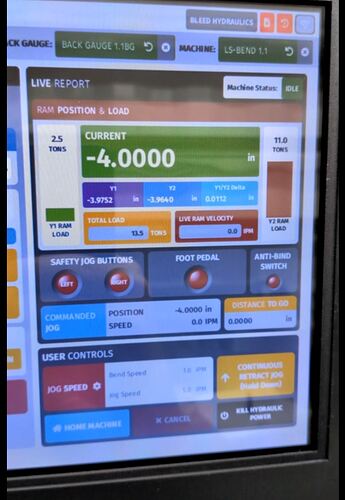

As far as the machine crashing and blowing the relief lines off - the problem was one of the pressure sensor electrical couplers not being installed properly from the factory - the threaded coupler was cross threaded, so it appeared to be connected and tight, but in reality the sensor wires inside were not connected, causing the machine to malfunction while pumping oil at full speed, blowing the lines off. discovered by Y1 / Y2 ram load not the same, machine would not allow homing, would not allow bleeding - had to manually bleed the rams, but the Y1 was still showing 2.5 tons. The machine would run in manual mode, but was still showing 2.5 tons after moving in both directions. I figured the sensor was damaged, but after taking it off, the coupler was cross threaded onto the sensor. I installed that properly, now everything works.

I’m guessing that if both sensors are functioning, that the servo pump motor would not run at full speed if the ram bottoms out? with one disconnected the servo was full speed mode overwhelming the relief lines? Is there a safety mode in the system that limits the servo in crash mode?

Yes that is correct. The system does have several different failure modes - rams going out of sync, tonnage maxing out, anti-bind system trigger, loss of data trigger. It sounds like your system lost the tonnage reading at the same time it triggered the PRVs, preventing the early over tonnage stop top from happening.