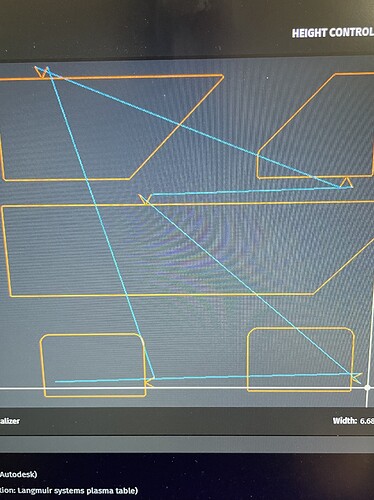

Hey new here just got it up and running. Running a pro with hypertherm 45xp Machine torch. Tried some 1/4” with Multiple parts and the cuts are good but from where it started to finish it is off a very little and the last part was cut out about 1/2” off see pics. Any help

It looks like one of the motor/lead screw couplers slipped.

The bottom picture is likely coupler slip

Another common reason for this (1st 2 pictures) can be thermal expansion of the piece while you’re cutting.

As you’re cutting the piece is rotating clockwise because of thermal expansion. This effect can have very similar results to what you see here.

Adding tabs can be helpful if this is the cause or making sure your feeds and speeds are correct and you’re not putting extra heat into the material.

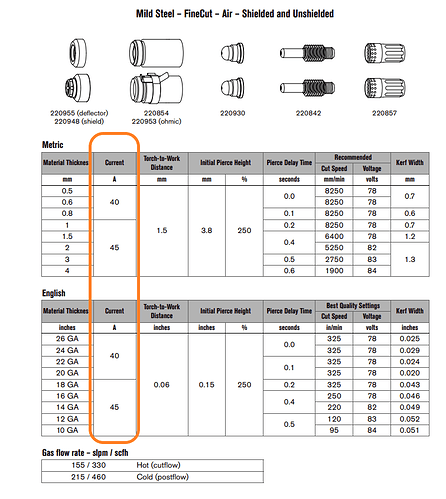

Just for information what parameters are you running and consumables?

Also having your torch too high will put a ton of extra heat in the material.

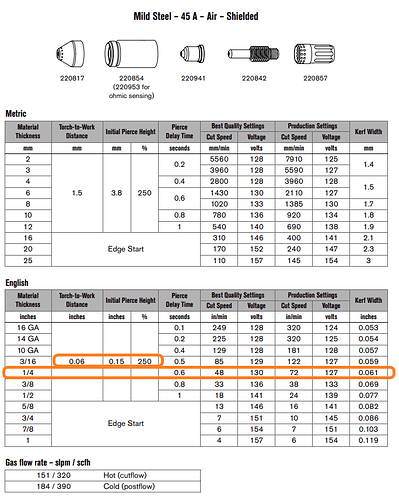

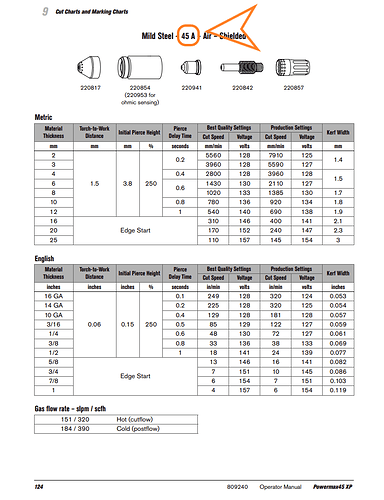

I was running at 45amps and 43ipm I think the book with the cutter is all in volts but that is the recommended speed for 1/4”. I will try to turn the amps down on the next run. But the 1/2” off had to be a slip I don’t know what else that would be. And thanks for the help

I was talking about the first two pictures

yes, 1/2 is more then a thermal effect.

could try product speeds for the thermal

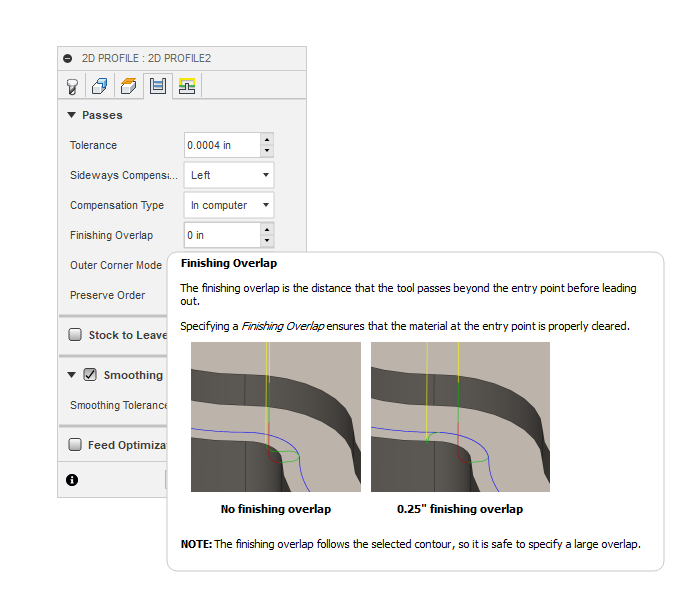

and "finishing overlap in the 2d profile - Passes menu in fusion 360 for the lead in lead out

45amps @ 48ip @ 130volts quality speed

45amps @ 72ipm @ 127volts production speed

after you check the your couplers. 3mm allen I believe.

the weight of the torch’s lead can sometimes have an effect too? observe it closely for strain.

you are welcome

I agree thermal expansion is definitely a thing… ![]()

Another I’ve had happen is when cutting lighter materials… If you are cutting at fast IPM or your rapids are very fast, and you have not clamped down the material, the table can actually shift under the material ever so slightly when x or y changes in direction quickly…

I’ve since added “Weigh down or clamp material” to my pre-flight checkoff list…

I realize this sounds like a no brainer but, I wasn’t always a hard core clamp guy!! LOL ![]()

![]()

![]()

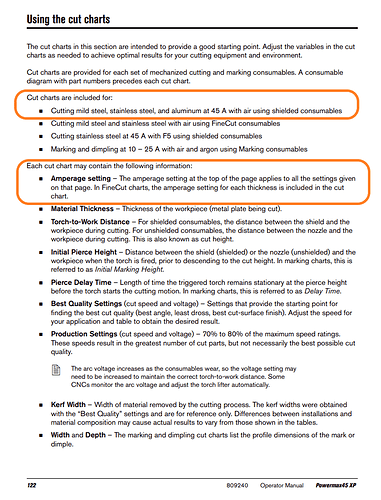

How do you convert the volts? Volts x watts= amps where you get the watts can’t find that anywhere. Why should you display amps and show volts in the book I think I’m missing something.

The volts are for your torch height control you don’t convert anything you write it in your nominal voltage box.

Hypertherm 45xp consumables are made besides where listed to run at 45 amps in your case. I’m sure in the fine cut charts there might be some 40 amp and 30 amp settings but if it’s not listed it’s 45 amps.

Ohm’s law will not help you here.