#1 In my shop nearly everything must be on wheels. My thought is to weld up a frame for my pro (with wheels) My basic plan is an angle iron rectangle to fit that the entire machine will fit into. I am wondering if the movement of the torch will have enough momentum to move the entire machine (even a small amount) and have a “consequence” on the cut? I’m sure there are those out there that also need the mobility and have addressed this! Any input on this will be appreciated!

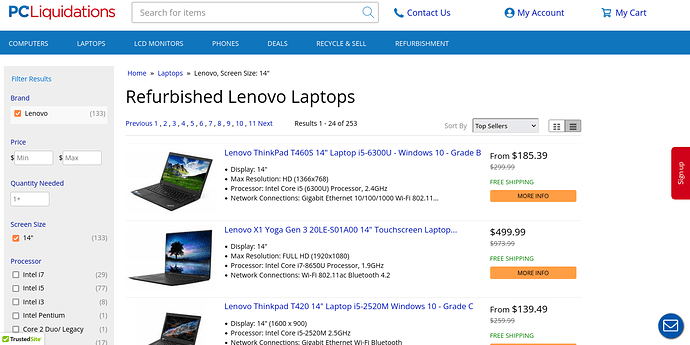

#2 The old guy (me) needs to come into the “laptop” world. I am cheap but recognize the need for a suitable and portable computer. I am “shopping” for a suitable laptop and on the forum I ran across a previous post that indicated that some guys are running an older laptop that is capable of just talking to the machine. Is this a good idea? My desktop computer has all the fusion and cad capabilities needed and I am wondering if this approach is a sound one? On the other hand, would I be better served to just bite the bullet and pop for a more expensive laptop that (in my mind at least might prevent computer issues that I don’t want or need) My “shop” is semi open and I am making an effort to minimize the “dust” by enclosing (with good venting) the area as much as possible.

All responses appreciated!

Footnote: VERY FRUSTRATED as my boxes have arrived a few days ago and I haven’t for various reasons even been able to get started on putting it together…DANG, life gets in the way!!!

Thanks in advance!!!

When I get around to it I plan to do a rolling base with leveling feet.

@TortillaMan has done it. Lots of different examples of rolling bases in this thread.

The folllowing is a snip of a post by @TortillaMan

Here’s what I did, if you want to gather some ideas…

Casters, levelling feet and 3 shelves underneath for sheet material storage.

Original legs slide into 2.5" square tubing to lock them in place. The substructure makes it insanely rigid compared to the original design.

TM

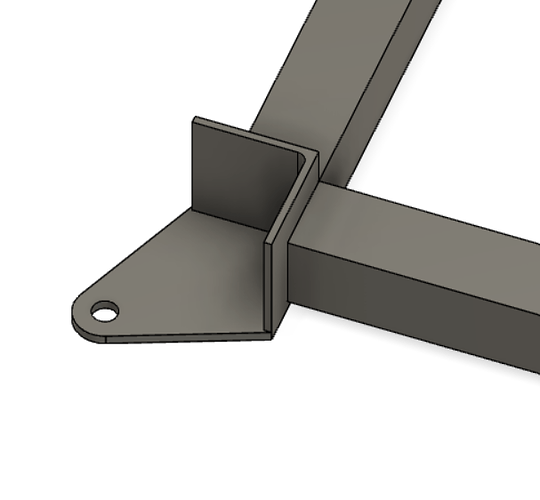

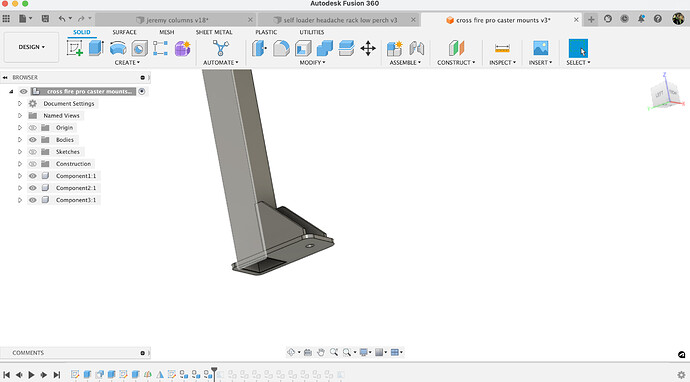

Here is what I had planned to do.

This is what I plan to do.

2 inch square tubing for the frame

L3x3x3/16x0,3" with a custom base plate for the legs outfitted with the original leveling feet.

I also plan to install some threaded rod with leveling feet. This will serve two functions level the table quickly and unload the caster wheels when not in motion to keep them from getting a flat spot… I guess I could just use steel casters and simplify it a bit… but I struggle with simple.

Attached is a quick sketch to give you an idea… not the final design. I haven’t decided on the base plate thickness or configuration yet. Still playing with it.

As far as the computer I would look at the Langmuir sheet posted on the website for comparable computer requirements and get one that meets their criteria.

No. I have mine on a rolling base and it does not move, even when I don’t lift it with the self levelling casters.

See this thread at beginning, and scroll down to July of 2022 to see mine.

Pimp My Pro- Mods and Addons - CrossFire ® PRO - Langmuir Systems Forum

My pro has been on roller base for over three years with no problems. The table legs sit in square tube and level table on roller base . My XR I welded the castors to the leveling pads that it come with ,rolls nice .

I bought a HP laptop from walmart 4 years back $230. on sale and have had no issues with it. Run Bend-Tech software,DeltaCad, Inkscape and sheetcam never had a freeze up any issues . Runs my Pro table.

Wow!! great ideas. I was thinking along the same lines but without leveling feet. Well now leveling feet are absolutely going to happen!

I’m not sure if this reply will get to all who responded but I thank each of you for taking the time to respond. As you can see I’m not a computer pro and am ASSUMING (uh oh) there is such a thing as a group reply ??? Hopefully this will get to all who took the time. I REALLY do appreciate it.

Caddy

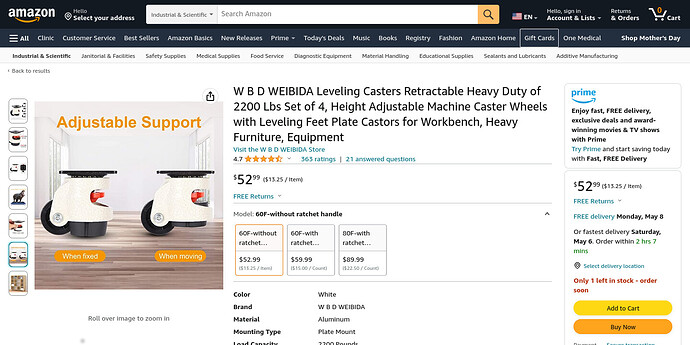

I used same casters as @rat196426 but cut out brackets and gussets then added cross braces in the y axis. I ve moved my table plenty and cut multiple index cuts on entire 8’ sheets with good rests. I left the original leveling feet in place for when the casters run out of stroke. Ill try to add a pic tomorrow

Nothin’ fancy. I just built the table. Put it where it was flat then placed a piece of metal under each leg and welded in place. The table held them flat while I welded. Has held up well.

Footnote [get it]: These casters are meant for very heavy loads. They are small hard wheels and as such, do not like some debris and seams in concrete more than 3/8 inch. They are meant for loads of one ton for the set of 4. I suppose when you have a sheet of 1/2 inch plate, it could get heavy.

Rat , What Bend Tech SW are you running and machine pushing it on, the Langmuir system? Maybe we need to talk offline.

I have Bend-Tech 7X, sheet metal/ plate and the msp templates.I use sheetcam for g code and currently using my Woodward fab tube bender to do all my bending,I recently installed electric over hydraulic motor and cylinder on bender and built new stand to make it vertical bender.I did have a air over hydraulic set up on it, slow and noisy.

10-4, Vertical bending seems to be the way to go using digital angle finder(s)

These casters are what I use and most of the time i don’t lock them.

Any of these Lap tops will run the table. Use a memory stick to transfer the cut files.

I know I share this a lot, but I’ve been using this little stick pc plugged into an old lcd tv with a Bluetooth keyboard mouse combo for two years. Only use it to run firecontrol.

Love it.

MeLE PCG02 Fanless Mini PC Stick Windows 11 Pro Celeron J4125 8GB 128GB Micro Desktop Computer Stick Support HDMI 4K 60Hz Wi-Fi5 Gigabit Ethernet BT4.2 on Business Office Industrial IOT Media Home Amazon.com