This is my first cut

It makes nice cut but it’s not cutting everything in my design especially the letters and piercing holes. I made sure the ground was on the piece of metal and put in new dryer filter with my air compressor and double checked the cuts in fusion 360. Wondering what the issue is - won’t cut on the inside or pierce holes

What are you using for CAM tool?

Are you doing the inside cuts first? (Absolutely necessary)

I’m using the fusion 360 I tried doing the inside and it’s still not working and a code keeps popping up losing voltage.

Your photo shows outside cuts. You can not do outside cuts before inside cuts. Think about why that might be…

Yes did another scrap with inside after your comment but it’s still not cutting the full design

Well, you’ll have to review your design with someone who knows fusion. I don’t.

I am having the same issue. I have also put a new air filter, adjusted the voltage knob on the plasma machine and have slowed down the ion thinking it was too fast. I am using hyperthermia toolset in sheet cam.

Any advise would be helpful. I have done different cuts and they all seem to have similar defects.

What plasma cutter are you using that doesn’t have the number of amps on the dial or display? Those speeds are way too fast for anything other than a Hypertherm at 45 amps.

I bought a Pro point plasma cutter. It is exactly the same as the razor weld 45.

I cut 14ga at 35amps and 140ipm. What is your air pressure gauge showing while the cutter is running? Those machines usually have the internal regulator set too low. It should be between 60 and 65psi while the air is flowing.

The Pro Point is another version of the Razorweld 45 sold in Canada. It does not use the X45 torch but uses the IPT 80 torch like the one sold in Australia. This means the smallest cutting tip you can get is 1.0mm/50 amp to do all your cutting, as with the X45/HYP45/FLAME torch.

Also the torch height should be set to .06" from cutting tip to metal being cut.

I would also recommend making sure you are getting the right air pressure from the plasma cutter as a lot of them have bad air regulators. !00 to 120 PSI in and the gauge on the front when cutting need to stay at 70 to 75 PSI.

And make sure the work clamp is on the metal not the table or slats.

Thanks M416 that is a lot of useful knowledge.

I don’t even have a regulator on my system so I am pushing 120 to 135. Is 135 too high?

I am using the tip that came with the torch but I will buy some new ones.

As for the .06. That is what I set it to all the time.

I had the work clamp on the slats not the work piece. I will also try that.

Thx for your help.

M416 is there a tool set you know of that I could download for the torch that I have

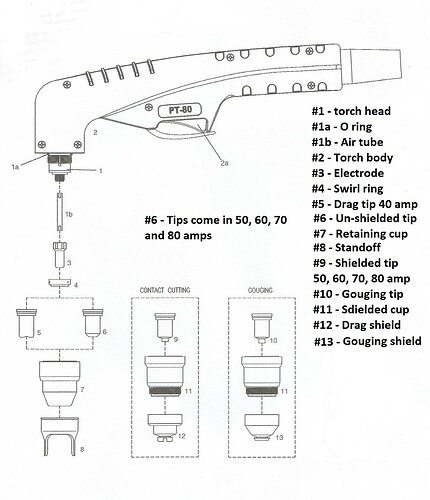

I carry all the consumables for that torch. Here is a picture of the consumables for that torch. Keep in mind that you only have a 45 amp plasma cutter so other then the 40 amp drag tip, and the 50 amp consumables is all that will work.

There is a community based Razorweld cut chart on this forum. You can make your own tools using that information and make changes after testing.

He really don’t need a cut chart. He only has one size cutting tip to work with. So you set it at 45 amps, 70 psi, .06" TH then all you need to do change the cut speed for what the thickness of the metal is.

Its not the best way to go, but just like the Razorweld with the X45/HYP45/FLAME torch that’s all you got to work with.

Turning the amps down won’t give you any finer or better cuts as you only have a 1.0mm/50 amp tip with a .040" orifice hole.

M416 are you in the Toronto or GTA area?

No, I am in Delaware

Ok so from what I have read about my plasma cutter is…

One size tip so kerf width is only one size

Maintain no lower than 70 psi

Full amp which is 45

And th .06”

But how do I know what speeds to work with (ipm)

Because so far on my test pieces not one has worked out yet.

Try 80 to 100 ipm. Look there is a cut chart for razor weld I think In then plasma cutter section