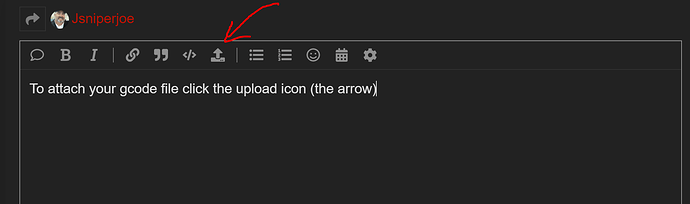

To attach your gcode file click the upload icon (the arrow) or drag and drop it into the reply window

As pointed out by @brownfox it is probably pierce delay. This is a well known issue with how Langmuir times the pierce delay and how Hypertherm times it. At some point hopefully Langmuir will accept the arc start signal output from the Hypertherm’s… but for now know that you will need to add a fixed value of around 0.3 to 0.5 seconds to all Hypertherm pierce delay values shown in the manual.

Further reading on Hypertherm and piece delays