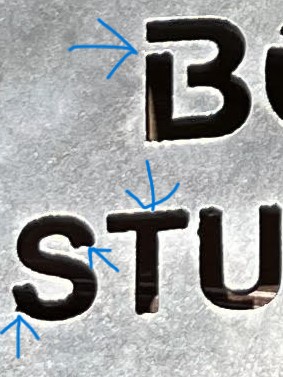

I’m having trouble with inconsistent cut quality. Some sections of the cuts have jagged or blown out edges. I’m running a crossfire xr with razorcut 45. The material in the attached picture is 3/16" mild steel, cut at 45amps and 55ipm. Zoom in on the letters and you’ll see the problem. Please help.

Welcome to the forum!

Are you located in Louisiana? If so what part?

Not sure if you lost some resolution importing the photo but when I zoom in I don’t have good enough resolution to see the cut issues you are experiencing. Could you take a closeup pic of the problem area.

What do your consumables look like?

What is your air system like?

Have you verified your cut height?

Consumables look ok, just the ones that came from the factory. I only have one air dryer/filter right before the plasma cutter, so it might not be enough for south Louisiana. I’ll try to attach a close-up picture. And how do you verify the cut height?

Absolutely you are going to want to do as much air drying there as you can… Work on getting that taken care of for sure!!

IMHO I’m wondering if your cut speed couldn’t be increased just a little bit. Was there a lot of dross on the bottom of the part after you cut it? Especially in the area of the lettering you point out? I have a feeling with a possible slightly slow IPM and additional slowing in area of the lettering VS. the outline cut, that the torch flame started “hunting” for more material to burn and caused your wavy-ness… You don’t see the issue any where else in the part correct? Again, just a hunch but, worth looking into as well as the additional dry air you’re looking for…