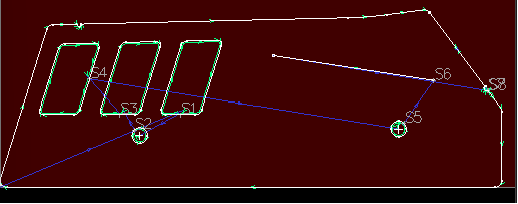

I am fighting a consistency issue. First pic show the exact same file but notice the lead outs . Im getting a trail off condition, but its not consistent. Any suggestions?

It looks like it’s cutting on the rapids(paths between cut loops).

That indicates that your plasma cutter is in 4t mode. It should be in 2t mode for CNC use.

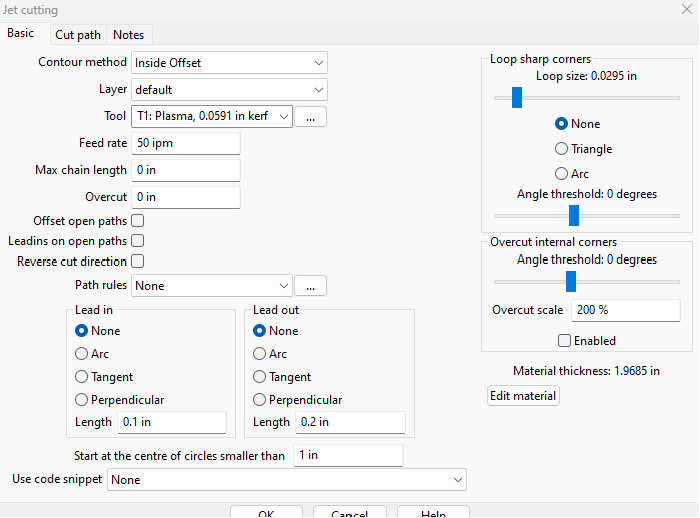

You should not be using “inside offset” unless you are setting up separate operations for inside and outside cuts.

If you select “outside offset” Sheetcam will automatically assign the correct offsets for inside, outside and no offset cuts.

I do have 2 plasma cut operations set up-1 for inside,1 for outside. I have no idea what 2T or 4T is, nor can I find it thru google ( I know its sad)?? Is it SheetCam or on the Titanium 45 Plasma cutter?

When I googled 2T 4T this was the first page on the list.

https://unimig.com.au/the-ultimate-guide-to-plasma-cutting/#:~:text=2T%20(two%20touch)%20means%20you,again%20to%20turn%20it%20off.

2T vs 4T

“2T (two touch) means you will need to hold the button down while you cut. In 4T (four touch) mode you will only need to click the button to ignite the arc, and it will stay ignited until you click it again to turn it off. This setting works the same way that a welder’s 2T/4T setting works, but there’s no foot pedal option.”

Never mind the 2t/4t thing. The Titanium doesn’t have a 4t mode. It does happen to display this behavior of not shutting off the torch on time and partially cutting on the rapids, though. You are not the first to experience this issue with a Titanium 45 plasma cutter, though this is the first time I have seen it with a Sheetcam user.

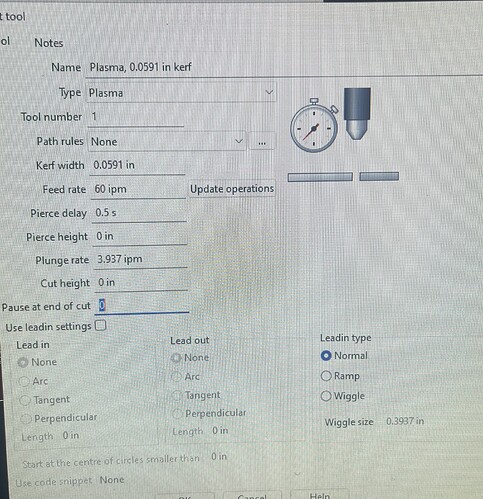

Can you post a screenshot of your Sheetcam tool that you used for this cut?

Here is a screenshot of the tool I use. I don’t have THC- thanks for your help

It is almost Freudian (or kismet) that your image has the area highlighted that may also be your answer.

“Pause at end of cut.” Some folks who have had your issue found a workaround by entering a small value like 0.5 seconds. This gives the torch a chance to shut off so that is not still firing while traveling to your next cut (rapids). You may need to increase the value of it, if it still occurs.

As Jim said, adding a pause at the end of each cut seems to help the users with Titanium plasma cutters.

Your plunge rate needs to be set to 60 ipm. You have it set at 3.937…

He doesn’t have a Z axis, so plunge rate doesn’t matter.

My mistake, I missed the fact that no IHS.

Also make sure the air pressure is set correctly as over pressure can some time cause this.