Hello All, We just ordered a 4x8 CF xr. Hoping to have it in a couple of weeks. We only cut aluminum, for the marine industry. Looking forward to sharing experiences and ideas.

Welcome to the forum Dennis.

I am saying “Lucky” to you as I barely have the space for the Crossfire PRO but it is adequate for my current needs. I have been to Galveston about 48 years ago (with a previous girlfriend and her family). We won’t get into that, though. Forget I said anything…(where is that delete key!!!)

Thanks, I think…

@Overboard Welcome to The forum

Aluminum is a tricky fickle beast for plasma cutting. It likes to spray a lot of aluminum around that ends up becoming a little flakes that ends up coming up bearings and rollers so paying attention and cleaning that machine all the time it’s going to be a big deal.

Aluminum is also way more susceptible to bevel, it absolutely hates cutting straight holes that are smaller diameter than the material thickness, and it loves to simply evaporate small geometry when cutting.

Once it’s dialed in though it can be great just beware it’s a big mess and definitely be paying attention to maintenance those little aluminum flakes are a nightmare when they start building up.

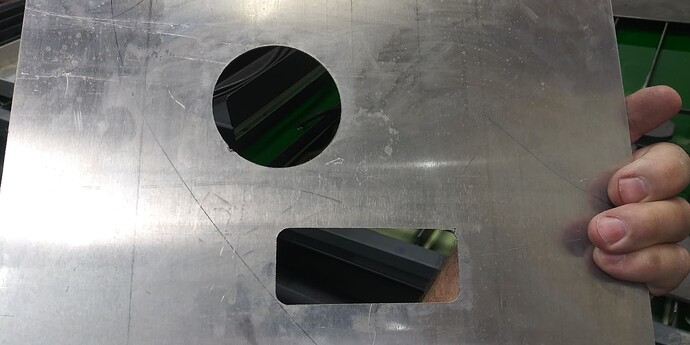

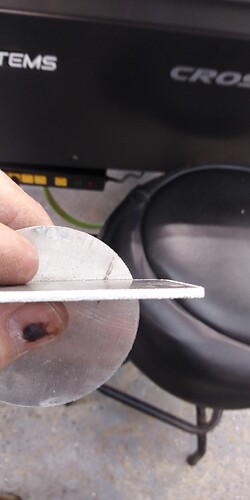

I cut a lot of aluminum on my XR with Hypertherm powermax 45 plasma cutter, cuts great with book settings. Minimal dross no bevel on this 14 gauge In pics.

It is messy like Tinwhisper mentioned though, I blow machine off with shop air then wipe down with wd40 when done cutting.

Yes, aluminum is tricky. We have had a 4x8 plasma table for about 6 years. We have experienced first hand the hardships of cutting quality pieces of aluminum. The vast majority of the material we cut is 1/8" sheet. Mostly aluminum boat stuff, but we do some “art” as well. Looking forward to our new machine!