After a bit of struggling, I got something cut. not great, but its progress. Are the wavy cuts and irregular shape a problem with my g code? or is it something to do with the mechanical setup of the machine ? Any input would be helpful. Thanks

make sure the set screws on the couplers that join the lead nut and motor shafts together are tight.

Is your torch dragging against the material?

Def. Check setscrews

I didn’t notice it dragging, I’m going to check the motor couplings when i get back to the shop…I was thinking something is wrong with post processing, if you look closely at the nose of the bomb there is a little bump at the top left, it’s the same on both and i started at different zero points. i’m using sheetcam but still have a lot to learn

Thanks

Download my fbomb remix on fireshare, it is proven and symmetrical.

Let us know how it goes.

If setscrews keep coming loose, remove them and drill a dimple on the shaft, reinstall setscrews

your offsets are in the wrong place as well. use a single layer and select outside offset, reverse cut direct and .2 lead in/out ARC and see how that looks.

ok, first, thanks for all the help. I think i have all the weird problems worked out…

i checked all the motor coupling bolts, they were all tight (I actually broke one…oops)

Next, i made a new cut file. this one is much better, however if you look at the first picture (The cut on the left) i still had the same problem.

Then… I noticed the power lead for the plasma cutter was lying on the Y motor (Second Pic). After moving the power lead things got much better (First pic cut on right)

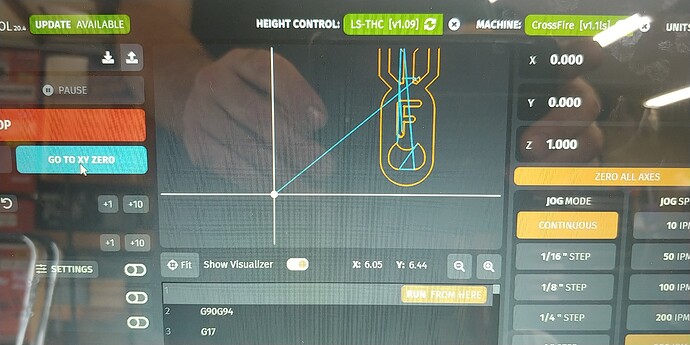

Ok, much better. so how do I fix the pierce? and why does firecontol not put the part at zero? (third pic)

I’m on holiday, away from machine BUT you need to play with start points and length of lead in, say tangent, .125 length and .2 delay at 30 amps and 100ipm for razor45 and 14 g steel