About ready to pull trigger on Pro. Whether it be new or slightly used in my area. Seames to be a couple for sale that people just can’t figure out. From reading here ,this seems to be a very helpful forum. Never been on cad/cam programs. Haven’t been on a computer in a couple years. I do a fair amount of steel fabrication. Is there any hope for me?

There is hope as long as you are willing to learn…

I would recommend watching plenty of work flow videos on fusion 360 or the software you want to use. Then you can decide or even download f360 the free version and play with the software.

Welcome to the forum!

If you decide to make the plunge there are lots of people who will help you learn along the way.

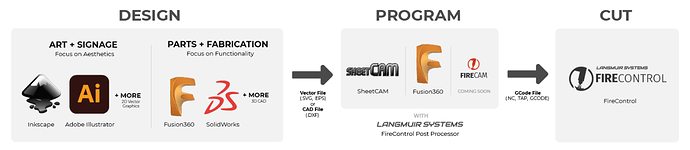

Here is the work flow:

- Design. Just about any program that will give you and SVG, DXF or EPS file can be used in the second step. (I am not familiar with EPS files…I just see it in the above graphic).

- Programming/Manufacturing (making the gcode). Basically you are left with two choices: Fusion 360 (Free to Hobby/Personal use) or SheetCAM (One time fee).

- Cutting. To control the table you have one choice…well basically, you have no choice: FireControl.

The part that seems to trip people up is when the machines are not talking together properly. To decrease frustration:

- Set up your table like Langmuir recommends, in the beginning. If you have other ideas, gradually change things after you have the table cutting successfully but not before.

- Pick a Plasma Cutter that is on Langmuir’s list of compatible machines. Never pick a High-Frequency start machine.

Plasma Cutter | Langmuir Systems - When you come to the forum for help, try to give as much information as possible. Try the suggestions given and report back.

- Most problems are eventually resolved easily

- Prepare to spend some extra money up front to have dry abundant air supply

- Don’t buy cheap consumables - all of us will be frustrated with the results including you. Again, if you want to try the cheap consumables after you have everything dialed in, that is up to you. Otherwise it is a waste of everyone’s time and your $$$.

Jim just gave you the go-by.

I’m new here too. My biggest hurdle was learning the ins and outs of what a plasma cutter needs to work properly. I underestimated the need for dry abundant air. My new air system has now surpassed the amount spent on the cutter itself. From the reading I have done on this forum (and my own very recent experiences), clean, dry air seems to be the most prevalent issue for getting good consistent cuts. That and dialing in the settings in Fusion (which there are lots of examples for the different materials you can cut on the table).

In my opinion, you can get by with a relatively low skill level on the computer stuff. You can buy all the designs you could want. You can download cut-ready files from Fireshare (in which case you don’t even need to have Fusion or any of the other post-processing programs), but you are tied to the design and cut path that was saved in the .nc file (that is the file that FireControl reads to control the CNC table to make the cuts (usually called gcode)). There are a lot of really good videos on doing to post processing and general “getting started” videos on Fusion. You can learn it if you are eager to learn. Pay attention to the terminology. Learn what a “lead in” is and why you want to offset it from your work piece. Things like that.

And 99.9% of the people on here will be glad to explain all of these concepts to you if you ask and follow the advice. I have had a lot of fun with this “hobby”.

General note on CAD software. I noticed that SolidWorks is offering a “maker” license for anyone making less than $2000 per year with their designs. Their normal price is $50 per year, but until March 10 they are offering it at $24 per year (our “full use” licenses at work run north of $3K per seat). SolidWorks is a TOP SHELF design package used by thousands of companies. I use it for work and also for “Engineering” parts for the plasma table or for 3-D printing. I will very soon be losing access to my work license so I needed to find a CAD solution for home. Just information if anyone needs it.

I recently bought that 1 year ‘maker’ license. Quite a deal. That reminds me, I was going to try and learn some of that program.

Definitely an amazing program.

I found their Sheetmetal workspace (not sure if that’s the right term for Solidworks) was very easy to use. I had a student’s license for a while.

Their sheetmetal tools are awesome. I have had some scaling issues bringing .DXF files into sheetcam, but all were easily fixable. Sheetcam sometimes applies the wrong units to .DXF (metric versus Imperial) but that is easily fixed with a scaling factor. I am an old Engineer who has used a lot of CAD packages over the years so I sometimes revert to old habits when using SolidWorks. My Son, however, is a certified pro in the package so he often has to help his Dad out.

LOL! I am looking forward to the day where my daughter can help me with Fusion! She already helps me with Perl, Ruby, JS, GitHub, etc…

Welcome

Pull the trigger. Before I even took delivery of my Pro I knew nothing about CAD/CAM. While waiting for delivery I spent a lot of time with the workflow videos and did a lot of research on YouTube and this forum. Fusion works great for me I only have the hobbyist version and it is a pretty powerful program for free. Good Luck the guys here are great like said before so if you need anything do a search most likely you will find what you are looking for.

Do you have time to learn over a period of time? or are you going to try and make things for people right off the bat?

I think you need patience and time. and just as the others have said you will need to spend money on equipment unless you already have it.

It is a fun hobby!

I came across a Crossfire Pro on Facebook Marketplace in Texas yesterday for $3,500. It was equipped with a Razor Cut 45 also.

Thanks everyone for the encouragement…still looking

Welcome to the forum. Can we assume you bought it?

Learn fusion 360 1st #1 there’s another part to fusion 360 it’s called CAM that’s the part that tells the machine what to do.

No I didn’t, I already own one. But I figured anyone looking for one would have a hard time passing this one up at that price. By the time you buy everything that includes the and Plasma cutter, THC and limiter switches, along with shipping and taxes you’ve got a substantial investment it.