I have had my table for about a month now . Just ordered a thin cut kit from plasmadyne. The guy i talked to there suggested reaching out and seeing what i need to do to make it work. He thought pierce delay. Im running the razorweld 45 . Thanks for any ideas.

Welcome to the forum. You will want to talk to George. His handle is @mechanic416 .

In general the ‘thin cut’ usually referred to as “fine-cut” need to be used at a lower amperage. And in general, they will have a smaller aperture in the nozzle which will wear down much faster.

You will blow thru those fine-cuts if you are trying to cut thicker plate. I think they are mostly recommended for 10 gauge and smaller.

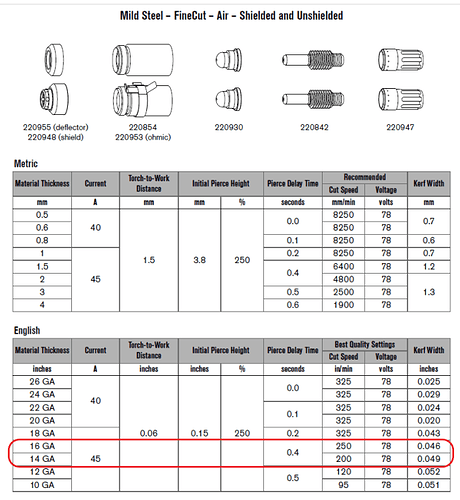

Here is a sample cut chart from Hypertherm 45XP with FineCut:

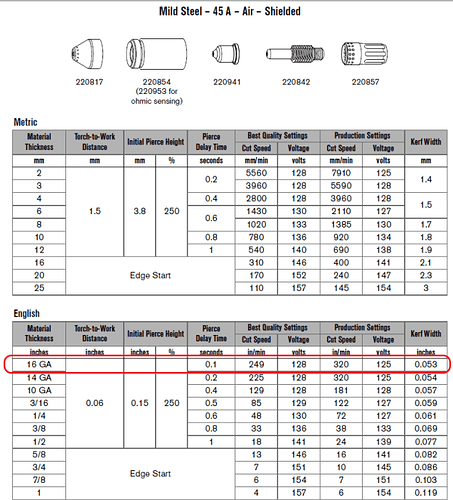

Here is Hypertherm 45XP with regular consumables:

So when you compare these two charts, the pierce delay is going to need to increase for the FineCut. Usually I hear people talk about the cut height being reduced but that is not reflected here. It looks like the cut speed is somewhat similar and the amperage is similar when comparing 16 gauge steel.

Now don’t use these numbers. I just used them as a reference.

Are you cutting stainless, mild steel or aluminum? Thickness?

Mostly 16 gage hot rolled. And i have done one sign out of 11 gage

Some people have done a lot of cutting of stainless with fine-cut because stainless is just brutal to get a clean cut with regular consumables…so much ugly dross.

But I know the FineCut is really nice if you are looking for more detail.

I don’t know about the settings for your machine and the only charts I have are for the regular consumables with the RazorWeld (posted by other users as it is really not published so detailed by RazorWeld). There will be others along to give more info.

Thank you for responding. And yes smaller detail. Right now doing sings . But definitely want to do functional parts also .

Are you using SheetCAM or Fusion 360 to make your gcode?

Fusion 360

Me too. I stuggled quite a bit but was determined not to spend anymore money and eventually got past the learning curve. Glad I stuck with it.

I started with fusion when i got my cnc router. I started having trouble with it and switched to carveco. So i was pretty familiar with fusion. Just new to plasma

Definitely not a bad design program. And being a machinest. I already knew alot of the terminology they use .