Ok so I pick up the langmuir systems crossfire about a month and a half ago. After assembly and installing the software onto my laptop I hooked everything up and did my first test run. Everything work great except the torch would not turn off. So after the company sent me a new relay I attempted test run #2 with the same results. I could get the Y and Z axis to function however the torch stayed on as soon as it was hooked up and I had to disconnect the torch control wire to stop the torch. Then the company sent me a motion control board, which I installed and gave it a test. Now everything seems to be functioning properly except the Y axis. It does nothing. I double checked if I had it hooked up correctly and everything seems correct. I then tried to move the Y axis using fire control Manuel controls and it moved about an inch and then no movement after that. Tried wiggling some wires around and still nothing. On the last motion control board all of the axis’ were functioning fine. So I tried to move the Y axis and Z axis plugs around and still no movement. At this point it beginning to become frustrating, I’m trying to be as patient as possible but I bought this tool to make my life easier and currently it has been doing the opposite. Has anyone had this issue? And if so do you mind elaborating what you did to fix it?

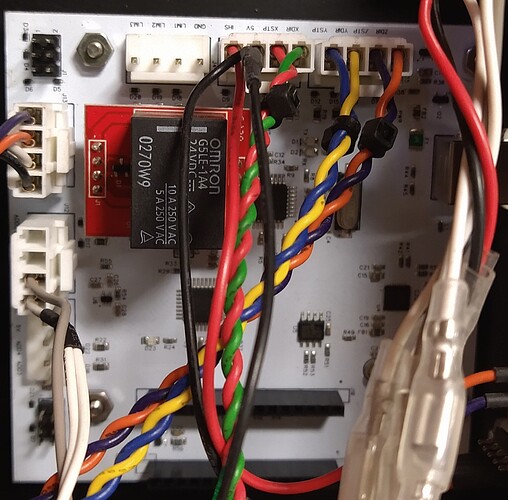

Its very likely that when you swapped the motion control board that a wire/connector was not installed correctly. Post a picture of inside your box and all connections.

post a pic of the entire control box with it turned on and connected. There should be green LED’s lit on the power supply and on all of the drivers.

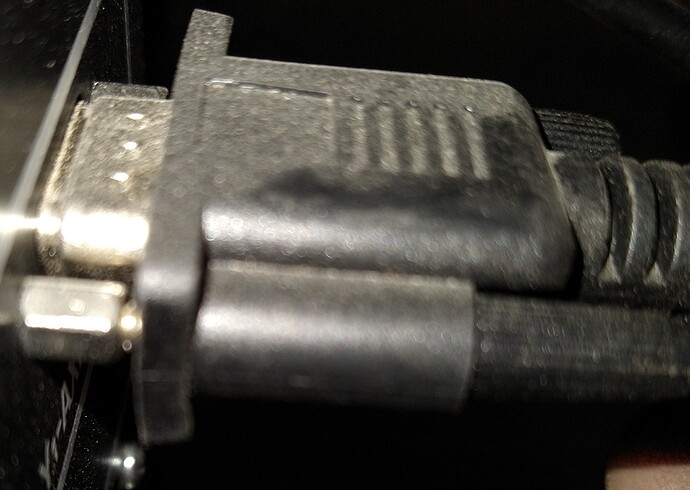

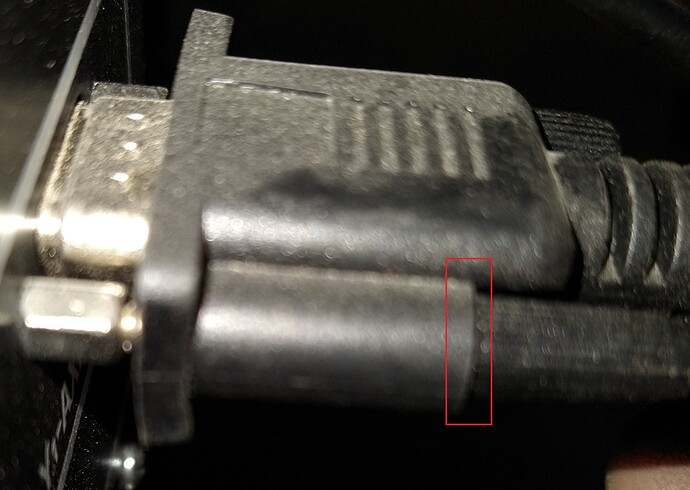

Ok I got that problem fixed for the time being. Here is what the issue was. Notice the gap between the plug and the nut?

The screws are as tight as they get and it doesn’t seat the plug. Which caused an arch between one of the terminals. So I had to take the plug apart resolder 2 of the pins one being the damaged one, then solder them on the row of unused pins below in zigzag pattern to keep them as far away from each other as I could. Then I had to copy that on the panel side. So after that I gave it a test run and everything seemed to be ok, I was stupid excited about cutting a very simple 4"x2" rectangle. However that excitement was short lived when I noticed the worm screw for the Y axis was not turning when the stepper motor was moving. So I then adjusted the set screw tested and it worked for a few small runs then the problem reoccurred. So I got the drill out started a small pilot hole just enough for the set screw to grab and it’s been fine since then. After a few more cuts the torch stopped working again and that’s currently where I’m at now.

We are aware of this issue and have shipped all recent machines with new screws to replace the thumb screws on the D-Sub connectors. If you didn’t receive these in your kit, please email us and we will send you a set!

You can also take the thumb screws out and grind the threads down halfway and they work like their supposed to.

Dang. We’ve seen a few of these on the forum. I’m surprised none of us thought to suggest looking at that.

I recently received my machine but I got washers. i used them per the instructions but I’m wondering about the screws because the washers didn’t fit the best. Thanks!

just grind them down.