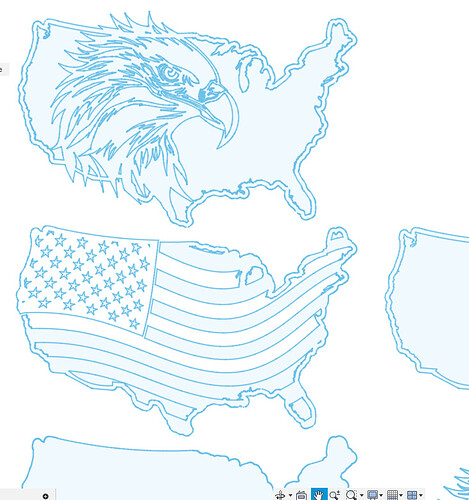

I downloaded a dxf for this three piece layer design (yep, probably in over my head). When viewing the dxf, it looks to me like there are a couple of cuts that will not be made. I am a self proclaimed new guy when it comes to all things Fusion, but I am a sponge. Am I correct in my observation?

Yeah, just looking at that image I’d say you’re correct.

Can you upload the dxf here so we can try and help out?

Edit: have you scaled the dxf to the size you plan to cut it? That would also be helpful to know.

Sounds like a linking constraint issue, although you don’t exactly state what your issue is other than an assumption of will or will not be cut out.

Think there’s a sticky I believe if you’re having linking constraint issues.

Kwikfab, if I am being honest (and I always am) I have no idea what a constraint is - much less linking them. I have however seen that selection in Fusion. When it comes to CAD/CAM, I am a preschooler at best. I am confident that I will learn it, just not there yet…

In short, it means a cut path you are attempting to create clashes within itself or another cut path.

You have a tool library in which you add certain parameters like feed rate, and more importantly, kerf width.

Fusion will offset your actual cut paths to make up for this difference and if a path collides with another, it will be disregarded causing a warning called “linking constraint”.

Ah, got it. I haven’ even went into manufature. This is still in design.

You can do a square cut out, and measure said piece in relation to the known dimensions in your design to find out your real kerf width.

Once you do that, you can begin to set up your tool library and create ‘tools’ for each specific gauge metal.

Reason for this is because the thicker your base material is, the slower your feedrate should be.

For example you could have 1 tool for 16 Gauge Mild and another for 10 Gauge Mild.

If using the same nozzle, you will enter the same kerf width for both tools, but each with individual speeds.

16 gauge may have a speed of 120 to 160ipm whereas 10 gauge may have a speed from 80 to 120ipm.

Now, when you have your design drawn up and you bring it over to CAM, choosing the appropriate tool will utilize the rules set forth with that tool (speed and kerf). You will then find if there are any issues when creating cut paths as your kerf width will be taken into consideration.

This is all explained in the software workflow on Langmuir’s page.

If you skipped it, I encourage you to go back and go through it as it’s very helpful and what many of us use when first starting.