I am wanting to buy a crossfire cutter but i would like to see if i can make designs with out hooking to the cutter. i have down loaded the software program says machine no connections and i can not draw . what can i do to design a part at this point. I am 75 and not computer smart

That program doesn’t design. It just runs machine. You need a a cad drawing program like Fusion360 or Librecad is a freeware program

If you’re just doing simple 2D things, like signs or yard art, then you can use something like Inkscape or Affinity Designer to make the art work and then use SheetCam to convert that into the type of file that FireControl uses. This has a much shorter learning curve than getting into a full CAD program.

thanks i tried Fusion 360 i could do it to complated for this old man i will try Librecad thanks again

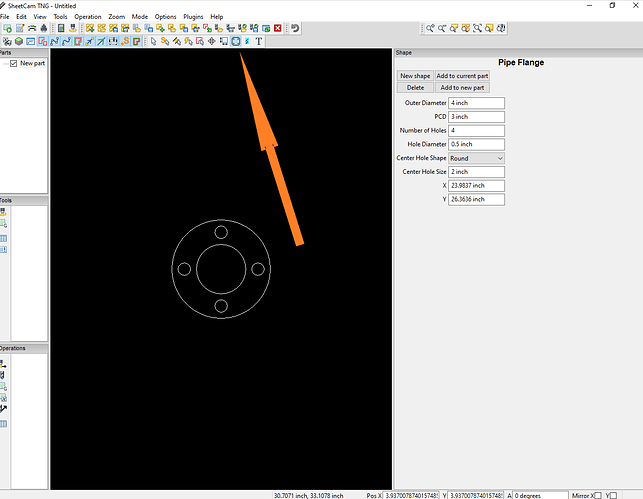

SheetCAM does have the ability to make some simple and common parts in its “Shape Cutting Library”

maybe a simple way to get started if the shapes suits you.

OMG! TW is giving SheetCam advice!!!

Now we’re all going to be out of a job!

Lol. A sign of the End Times no doubt.

but back to @billeoff …

Bill…I am going to be totally honest with you…CNC plasma cutting it 75% computer work…

Many people buy these tables thinking they can download anything and go cut…and end up getting frustrated at the product and the company…when in fact 90% of the problems we help with here on the forum are user error…

Langmuir has a great basic description of workflow on the website.

https://www.langmuirsystems.com/software

I will explain a few basics if you are not aware…

Plasma…if you do not have a plasma torch…be careful what you buy…this can be the weakpoint in the system. buy the best you can afford…do not buy off shore knock offs…they are not overly reliable and made well…which leads to poor plasma arc and overall frustration

Air.…A plasma needs to be supplied with sufficient (volume) air that is dry. Most people run off 60 gallon single stage compressors…some run smaller but it limits you to the amount of cutting you can do or burns out the compressor. Dry air is critical…it greatly affects the finish of a cut. drying the air is not an easy task if you live in humid or areas where the temperature fluctuates. A lot of reading and research is required to have the right air system.

Back to the computer part…

I do this as a hobby and I am retired and I spend more time in front of a computer than near the table.

Like I said 75% of the time is working on the design. Even if you buy a design off the web or from a trusted source there still is the time required to check the design…tweak it.

Working with your design is called the CAD part…Computer Assisted Design…there are many software options out there to work with…many are free…many you pay for and many are confusing…some are simple…you need to find one that you like.

Next is the CAM part of the computer work…that takes your design/sing/artwork drawing and converts it to a file format the Langmuir table can read…this is called Post Processing.

In this phase you program in your torch speed, Plunge rate, cutting height, inside cuts…outside cuts…lead in and lead outs…all the details needed to make the machine do what you want…

Now we get to the Table…at this point is when you need to have the computer to hook up to the table and start Firecontrol…you load the program you made from the post process stage into Firecontrol…

Still not ready to cut yet…with Firecontrol you now line up the torch where you want to start…turn on the plasma…adjust the amps you need to have to cut what ever thickness of metal you are using…

Press start and 3 minutes later you are hopefully done…

that is bassically the work flow…so be careful if you are not computer literate…

Wooooo! That’s a feature I didn’t know sheetcsm had. Guess I should explore the software a little more beyond just post processing with it.

Never used sheetcam for moar than simple cam, thanks