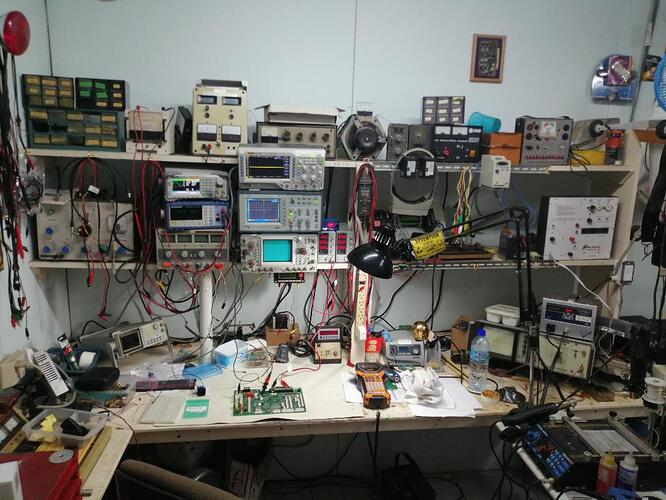

Thought I would post a couple pics of my workshop here at the back of my house in Trinidad. I expect to be ordering my Crossfire XL within the next few weeks. I’m a semi retired electronics engineer, I still work servicing and consulting in the Biomedical field mainly Sterilization and Life-support Systems.

Recently moved the CNC Grizzly Mini-Mill closer to the 9x20 Grizzly Lathe on the shop-floor to free-up space for the intended Crossfire installation.

CNC Stuff in the shop presently are: two Rotary Engravers/Routers, Laser Engraver, 4-Axis Mini-Mill and 3D Printer.

These are complimented by: 9X20 Lathe, 4x6 Metal Bandsaw, Radial Saw, MIG and Stick Welders, HF Plasma Cutter and a bunch of grinder, sanders and other cool stuff.

On the electronics side, loads of cool electronics instrumentation in the Lab which I use for servicing and calibrating medical equipment and quite a bit of R&D stuff too. CAD/CAM Computers in the Lab are Panasonic Toughbooks running Windows 10, AutoCAD, SolidWorks, CamBam, etc.

CNC Control computers on the shop-floor are Dell Optiplex 780 running Win XP and Mach 3.

Shop air is provided by a 6-hp 60-gal Campbell-Hausfeld compressor with auto-drain.

Dear Mr. Cletus, I’m torn between saying “YOU SUCK!” or “Remember when I gave you some advice, Sir. And, you know, how helpful it was?”

Nice setup. Ok, so I’m not going to move to Trinidad/Topago, wherever that is (I’m thinking any place that can’t decide if it’s Trinidad OR Topago has got some issues), but I do have to say, Nice setup. Now, whatcha gonna do with your CF Pro? And, BTW, do you do your own electronics design or do you need an occasional visit from a World Renowned Electronics Engineer? Huh huh? Do ya?

Cool,

T

The first thing I thought when I saw the pics (awesome by the way) is that this dude would enjoy a YT channel that I enjoy watching - Mr. Carlson’s Lab! The mancave has the same vibe!

Thanks for sharing with the forums!

Well, Trinidad & Tobago is a twin-island state in the Caribbean (Trinidad is the Southern-most island neighbouring Venezuela). Yes, I still do quite a bit of custom electronics design work. Once upon a time, I was Chief Engineer at a Samsung Consumer Electronics Assembly Plant here. Semi-retired, I sell and support medical electronics equipment here in the Caribbean for Avante Health Systems of Louisville KY. I’ve got an upcoming hospital upgrade which encompasses the installation of a new Central Sterilization Dep’t., Radio Therapy Suite and a whole bunch of other stuff. Usually I would farm-out all the custom bracketry and fittings to a Waterjet jobber with my cad drawings, but decided to keep it in-house this time around (and probably from now on) as this will pay for the Crossfire XL and then some and anything after that would be gravy. Not quite enough room for the Pro.

A few associates here keep asking when I’m getting it, so I expect it will pretty much earn its keep and help put some choice steak on the grill from time to time.

Hoping to order it within the next month, once a couple details are finalized with the contract and somebody hands me a job mobilization check… LOL!

Hahahaha!.. I know that channel well …Just love what I do, so really, I’ve actually never worked a day in my life!

I like that gauge! Nice! I’ve used similar on DC…oh…how these forums create new projects for me…sigh…

I agree with @James5, nice gauge! Where did you get it?

Never mind, found it: https://www.amazon.com/Current-Amperage-Voltmeter-Multimeter-Transformer/dp/B07JB9B2QL Neat!

Ok, James, we’ll need to see who will beat this one!

Hahaha! …Just waiting on a check to mobilize a project, it’s all approved but it’s in the hands of the “bean-counters” now. Once that’s in, I’m all set to order the Crossfire LX. Decided on the PrimeWeld CUT60 for it.

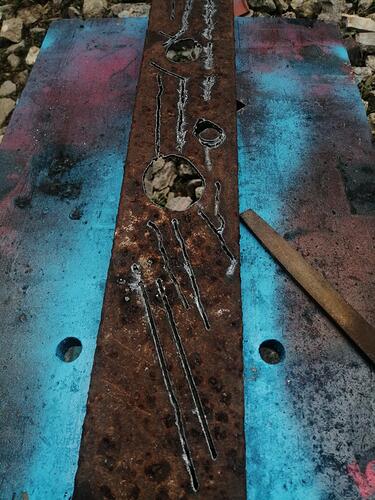

Well I spent some time today getting used to manual plasma cutting, fooling with settings, etc. with my Lotos LTPDC2000D plasma cutter. Been hacking away on a rusty old piece of 1/8 steel. Had the boss lady observe the power meter and take a pic. So, on this machine 50A and 75psi (dynamic) gets the job done like a hot knife in butter, very little dross, using a fairly fast draw of the hand. During pierce the ac current goes to ~36A and settles to ~27A during the cut. I was interested in finding that electrical data, but could not find such in my searches.

Also built me a “Motorized Straight Cut Rig”, this will help me rip a sheet of steel into manageable pieces for working on my Crossfire XL.

I like the hinge on the switch panel. Very ornate!

And, when you aren’t cutting sheets, you can use it in your driveway to cut up those stones!

Ultra simple rail system, using electrical conduit and it’s fittings, a 3/8" threaded rod and an old DC Gearmotor. Light dimmer, and full-wave rectifier gives it speed control.

Are you really using braided hose to hold the nuts on your threaded rod?

Gobsmacked! That’s what I am!

Ah, I see that’s your shaft coupler, even better!

I can see the next CrossFire design will have a significant cost reduction!

Hahaha, yes and it works a peach. I can get up to 30 inches per minute. seems to cut 1/8 best at ~20 inches per minute.

Cletus…I am a Facilities Manager at a Hospital in Canada…and I can tell you are a bio-med guy…seriously electronic based…a little detailed retentive…but always looking for a new challenge.

Seriously envious of your shop equipment and your stuff…

Thank you so much for the compliments!

I just pulled the trigger on the PrimeWeld CUT60 on Amazon

you get the same cost on prime weld web. free ship.1-856-537-4368… real nice to talk and deal wait too. I 1st got the primeweld 225 TIG stick real nice for the money more for the bang . lots more very well made also a + same with the plasma cut 60 works great as well made very too ! no its not a

hypertherm plasma cuter that cost thousands and it work dam good ! I wish I could great one but being old and handicap and fixed income [ lost my pension ] putting this way I am BROKE . am very happy too have what little I HAVE also died a few times and hospital very long time like 20 operations years .so very happy to be here and the things that I still have … THANK GOD . HAVE FUN WAIT YOUR NEW PRO > I can not wait till my pro comes ( August they say ) make a great birthday present ) august 24 now that be nice to have setup and running that day . sorry for rambling on . have fun