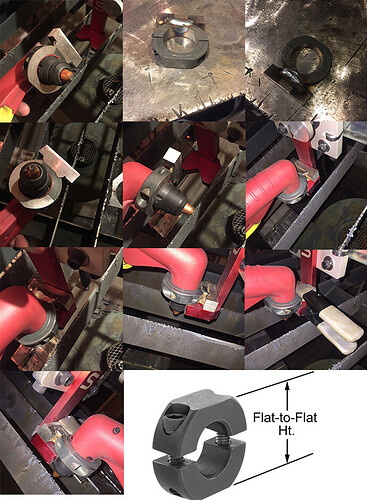

Okay, so new Crossfire owner, first time poster and I’d like to show some of my mods that I’ve done in the process of getting my system up and running. The first thing I’d like to share is my Torch Mount solution. (See attached photo)

I do not like the torch mount as it came on my Crossfire (No Height Control) and I’ve seen some other people having problems getting it to mount properly and that sometimes, the cutting shield is in the way, but I couldn’t afford a magnetic holder or machine torch so here’s what I did: My cutter is a very cheap CUT-50 with Low-Frequency Start that I found on Amazon (I simply couldn’t afford a more expensive cutter), but this should also work (in theory) on a Razocut, ViperCut or Hypertherm. I measured the Diameter of the torch right before it intersects with shield. (it came out to about 1.280") then I ordered a two-piece clamping shaft collar with wrench-flats, and installed it on the torch, just above the shield cap, so that it seats on top of the torch mount and properly seats the cutting nozzle firmly in the ‘V’. Once I was done with all my measurements, I fabricated a little spacer, then welded it to the wrench flat of the shaft collar (not the prettiest welding job) so once seated, it butts right up against the front of the adjustable torch holder and is flush with the sides as well. I then hold the whole unit in place with a simple spring clamp. It seats very well and I can tell by feel (the right side is a little off, but the left side is perfectly flush) whether or not it is properly seated, and have solved the problem of not having enough ‘meat’ on the torch for the bolt-on portion of the mount to get a hold of, and have basically eliminated it altogether… No more taking five minutes to unbolt the mount to clean the tips of the consumables off or change them out. This also comes in handy should a crash ever occur. -If the torch were to hang up for whatever reason, the clamp would slip off of the collar, and it would simply pull itself off of the mount (like a magnetic machine torch mount) and not cause any further damage.

I got this idea from a previous employer who had me running his PlasmaCAM with a hand held torch and similar configuration and instantly saw the benefits of installing a shaft collar on the torch head for better seating. Again, it takes some tight measurements, some fabrication, trial and error and a LOT of grinding so that it fits and seats just right. And no, this configuration might not work for everyone; but it works very well for me and I recommend it to others, especially if they’re having problems getting their torch to fit well on the torch mount.

Here is a link to where I got the shaft collar from. You’re going to have to carefully measure the outside diameter of your torch and then find a collar with a corresponding Inside diameter (‘For Shaft Size’, Mcmaster-Carr’s terminology) that closely matches it, and is possibly even a little larger as the shaft collars are usually oblong versus perfectly round. It might even take a couple of iteration to get it just right, but if you can make this configuration work for you, it is really worth the effort.