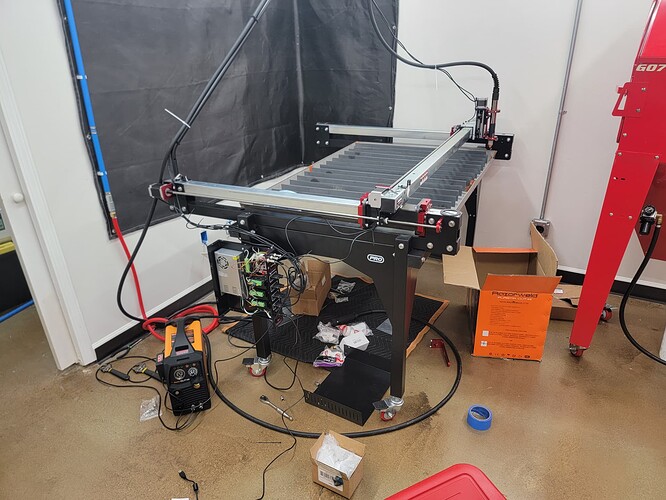

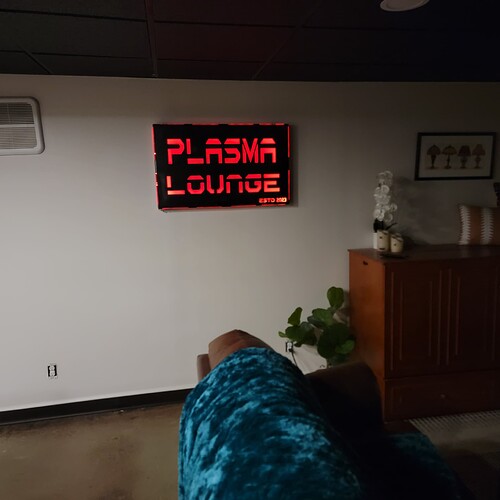

I convinced my wonderful fiancee to let me kick out a tenant from our basement and reach for my metal fabrication dreams. What had been effectively a studio apartment became an additional living/guest room, and the back half is now my shop.

Because I’m using my CFP indoors, there are some precautionary steps I’ve had to take. This is just what I’ve done in an attempt to keep things clean and safe inside.

My air system is a 60 gallon compressor, aftercooler in to a Tsunami water separator, then in to the tank. After the tank, air moves into a drop system I made out of pex and a bunch of fittings, then in to 3-stage cleaner/seperator/drier on the wall. From them there, it goes from the closet in to my shop, drops for the machines, and ultimately in to the garage next door. Everything is 3/4" Pex. There is another desiccant drier and a regulator at the table.

First thing I did to keep the place clean was put up a welding blanket on the walls my table sits up against. Woohoo.

My Ms. added curtains between the two spaces to help cut down on cross-flow mess. I probably don’t need to tell you this still resulted in a nice fine black dust everywhere.

So I started on ventilation. I’m still working on this, but this has been the process.

I bought 2x 850CFM sucker fans and mounted them in the drop ceiling directly above the table. I ran duct through the ceiling and ultimately exhausts outside the house through dryer flaps.

This was helpful, but not sufficient.

While I was messing with the air quality thing, I found myself with way too much steel laying around with no organization whatsoever. My easy cheap solution was to build a box with wood and store it in the shop.

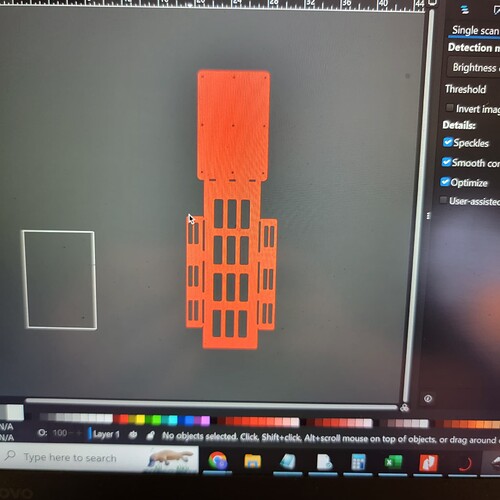

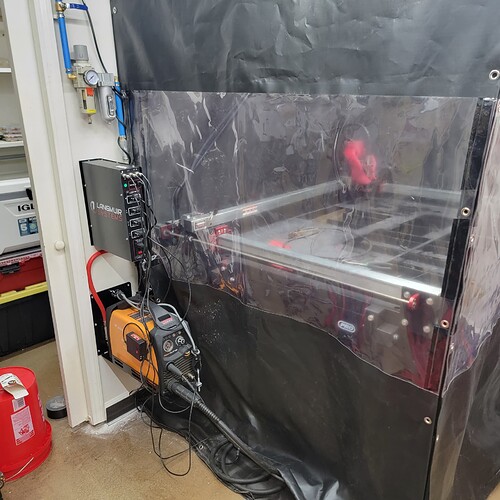

Next thing I did was add an enclosure around the table. I ordered some custom-sized weld/spark safe curtains and some track material. I used the table to make some wall mounts that ultimately anchored the tracks in to the sheet rock.

Again, helpful but not entirely efficient. The curtains aren’t held to the walls or the corner pole, so smoke coming from the sides of the table was just floating out of the enclosure. I also determined my weld blanket on the wall needed to be extended to keep the walls clean.

Proxima, I decided I was tired of the exposed air system in the shop room, and my drier/regulator set up was janky. I made the plans to clean up the whole shebang.

I chose to remote-mount the control box outside of the enclosure. I also wanted to store the plasma machine outside of the enclosure. Both for the reasons of long-term cleanliness, as well as the ability to turn on/adjust them both without opening the curtains. I cut some mounts for each unit, bent them on my homebrew brake, and anchored them to the walls. Each is 1/8" steel. I streamlined the regulator/drier set up as well.

With the control box to be mounted away from the table, I was able to narrow the enclosure by about 6". This gave me enough room between the enclosure and the closet door to fit the plasma machine. I also added velcro to the corner post to stick the curtains snug to it, and made L-brackets to anchor to the wall for the same purpose. I also tucked all of the air plumbing in to the ceiling, so it’s not visible running all around the room now. Much tidier.

This brings me to today. Because of the distance between the table and the box, and the curtains between them, several of the cables are too short to work properly. I extended the wiring today for my limit switches, and ordered VGA extensions to add a few feet to the X axis and one of the others (I forget which off hand). My plasma mount was also a little springy, so I designed/cut/welded some arms to it to keep the machine sturdy.

My hope is that with the enclosure fully sealed up, the fans will generate enough suction to keep up with the torch. If this is still insufficient, I’ve already talked to one of my HVAC vendors about forming a duct that will allow me to mount a whole-house fan on the wall next to the table. Ain’t nothing gonna get out of the box at that point.

So there it is. I’ll update as it gets buttoned up in the next few days.

This is how it sits as of tonight after cleaning up my messes.