My Hynade has ran great for 9 months, but finally quit firing, and will now not fire with the machine or hand torch. Appears to have a dead board. Hypertherm 45xp is now on the way.

You’ll like the hypertherm!

Yes, it was always the plan. The Hynade got us started in class and then took a long time to die. With the education discount it really isn’t that high for the hypertherm. I never cut thicker than half and usually less than 1/4 so I got the 45xp should be all we need. I also ordered the cable from Langmuir so no more soldering for me.

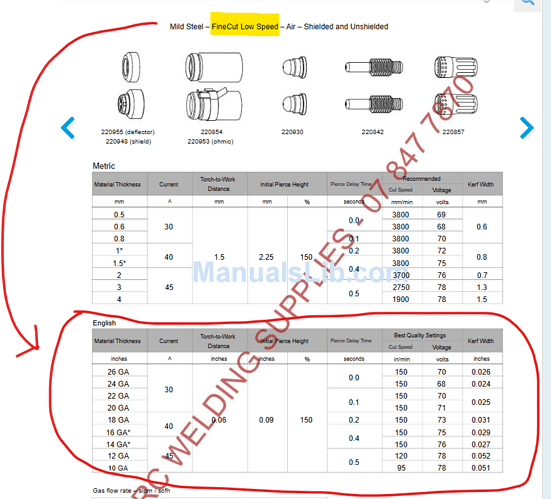

I run fine cut tip on many of my projects. I’ve had really good luck with these cheaper consumables. Once I got my moisture issue under control 8 months ago. Make sure you look at the consumables chart and get everything correct for torch. Enjoy the new toy and setting it up.

KEMAO 220930 FineCut Nozzle 220842 Electrode, 40Pack, Fit for Hypertherm Powermax45XP/65/85/105 Duramax Torch Consumables https://a.co/d/62lgPW8

Do they last as long as the hypertherm factory? Also do you run the book specs on 14 gauge or do you lower amperage and lower the speed? I have always run my Hynade at 35 amps and 110 ipm, but wondered if the hypertherm would be better at full power with the fine cut.

Hypertherm consumables are the best hands down, but you pay for them. I do my own thing and what works for me might not work for someone else. I do a lot of cutting and couldn’t tell a difference in my consumables. I think since February when i purchased them I have used 4 different tips and electrodes and cut things all the time. I really keep eye on my desiccant beads, so no moisture makes it to my cutter.

I use the book settings the first time and fine tune if needed but hypertherm is really good on settings.

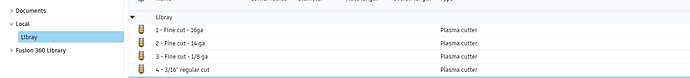

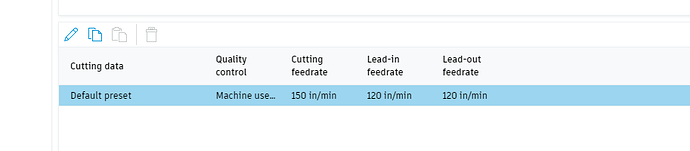

Look at how I do my tool library.

Only real difference in 16ga and 14ga is amperage. 40amps to 45amps

I do slow down my lead in speed and use 0.6 for my pierce delay time