I notice that my cuts are a touch smaller than I designed them. How much larger should i go on design to compensate for what I guess is torch width. thanks

Are you using Fusion? Put in your kerf width and it does it for you.

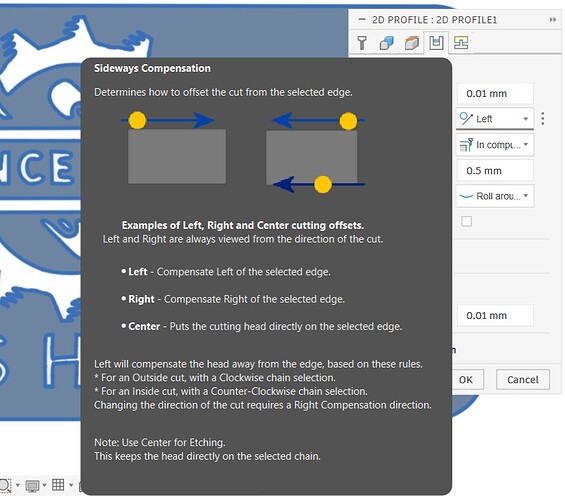

Are you cutting with the Compensation set correctly? For example, are you cutting on the outside of closed loops (rectangles, circles) and in the center for open loops (lines)?

F360 setting during Tool Path generation:

Like Big Daddy said, you need to enter the correct kerf width, so the CAM software can put the tool path in the right spot.

Normally I would reference the hypertherm manual but this is also a good way of coming up with your actual real world kerf width.

For a test design a 2x2 square and then make your tool path to cut a center line cut for the outside perimeter.

A good example would be.

You make your cut you measure the square.

It ends up being 1.95 " in width.

2.“- 1.95” = .05

Your kerf with is .05 for that particular material and those particular parameters.

You could also do a 1 in hole on the inside and do a kerf width check there too. Then add the inside and outside kerf width together and then divide it by two.

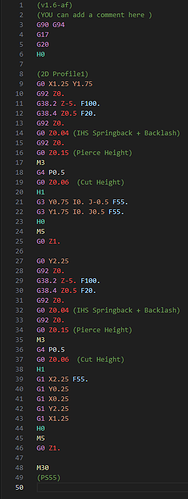

I made this video a couple years ago going to the process of making a test Square infusion 360.

A simple walk-through Fusion 360 to g code for plasma

Pretty much, all of the above information.

You also want to ensure cut height is set correctly before going about figuring kerf width as incorrect height can directly impact the “kerf” you measure.

That really is a fool-proof way to get the kerf width. At first I thought “No…you need to divide by 2 something” but by using center compensation you are basically telling the post processor to ignore the current “kerf width.”

I am going to book mark that video. Thanks Tin!

So can cut speed, nozzle type and consumable wear, material type, etc

@justgregg It’s ideal to run your kerf test after you’ve worked out all these other variables.

Only perform a Kerf width test with brand new consumables.