What is the Maximum material capacity of the Punches they sell ?

I wasn’t aware that punch dies were even an option at this time. Correct me if I am wrong. They did send me a list of the bending dies that I wanted with the machine. Punch dies was not on it.

They’d be rated way more than 25 ton. I wouldn’t worry about them on the Titan. The smallest press we have at work is a 60 ton and you can bury the punches into the dies without causing damage. The bigger press has exploded a few dies but 175 ton can do a lot of damage.

he is calling the upper die a punch I think

“I suppose I am not very familiar with the terminology yet. ![]() ”

”

@custommetalmke Does that mean you could bend at 25 tons with a small (~ 1" width) section of the Gooseneck punch (punch #5) without damage to the punch?

Tops are Punches. Bottoms are Dies.

I got it now sorry. I’m ßure I will pick this up soon.![]()

Yes, but you still need to pay attention to the thickness of material you are bending. Always reference the tonnage charts before you begin. 1" bottom with a goose top you could safely bend 10ga anything thicker could over load the die. Also important to set your bottom. You can overload a die and punch just running it past the bottom. I’ll say it now though 25 ton won’t really do much damage to tooling.

Thank you for the information @custommetalmke. I have been going back and forth trying to figure out what punches to get. Going with the 4 way bottom die. I don’t plan on doing any acute bends in the near future. Mostly 90 degree bends for boxes and pans. Some “J” bends too (in thin AL) . I guess I’m not seeing a real reason to get anything other than the Gooseneck die for my needs. Mostly bending .0625 to .125 5052 aluminum and maybe some .125 to .25 steel (very rarely). Any thoughts?

Hopefully this will help @Clevorracing too.

Goose top and the 4 way bottom will get you about 90% of what you’ll ever need. My suggestion is make sure you are think about the flange sizes you plan on bending. You may run into a situation that the 4 way won’t get. Anything small than half the die opening plus 1/32" won’t bend. It’ll slip into the die opening.

Thanks for the advice! I hadn’t considered the flange size. I will definitely keep that in mind.

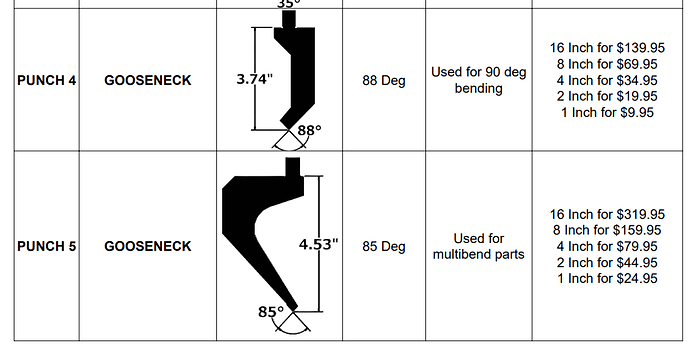

Is there a use (or specific example) where the Gooseneck Punch #4 would be better than the Gooseneck punch #5?

Thank you again for the help @custommetalmke !

Goose 4 is for 90° bends and goose five is for deeper pan bends where the punch can avoid contact. 4 is more useful in my opinion for normal bending.

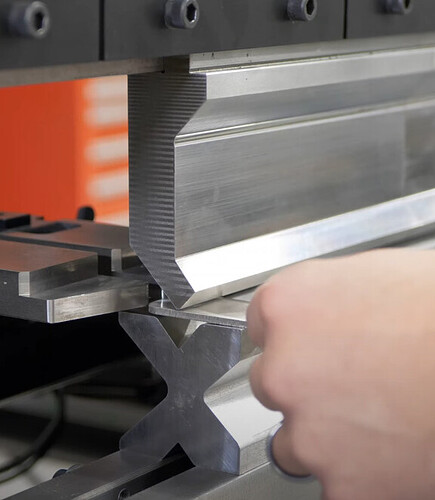

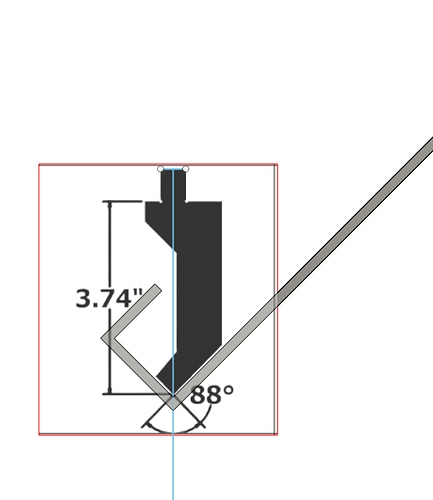

Do you see any reason why I couldn’t use the Gooseneck Punch #4 in the opposite direction that it is shown? Turned around 180 degrees so the punch points away from the operator. It seems the tip of the punch is aligned with the center of the tang.

Looking to do a “J” Bend on the end of a long sheet.

Thanks again for answering all of my questions @custommetalmke

You can reverse a goose. The tip is still center of the die. Most of the time the goose does mount in the opposite direction from what the picture shows. The picture shows a reversed goose.

Thanks for sharing this info you guys! It helps everyone

Is there a way you could share the list of dies they sent you. I didn’t receive that email and would like to see what they are offering.

Nevermind I saw you did post in another thread thanks.