I have a Primeweld Cut60 paired with my table, and i upgraded to the UPM 105 torch (hypotherm consumables). Ever since i installed the torch, the first pierce is always too short. Every cut looks great other than the first one. I can set my pierce delay to whatever number, and the first pierce is always 0. Any help would be appreciated!

you mean pierce time is 0?

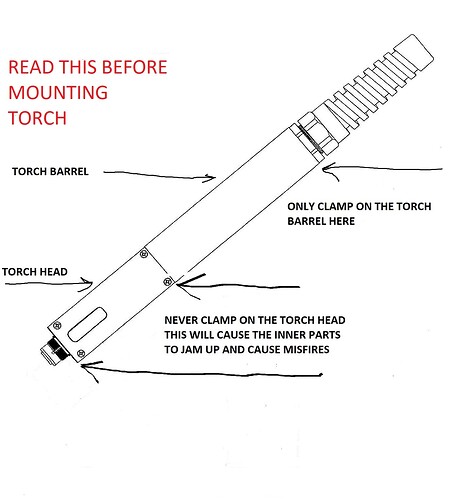

I am not sure this is what’s causing your problem, but you have your torch is mounted wrong. You should never clamp to the torch head. Both clamps should be mounted to the barrel.

I don’t have the Langmuir machine torch mount… but I think you can flip it or something to get it higher up on the barrel.

this is a snip @mechanic416 posted a while back

Nice catch, I glazed right over that!

Both Knick and Erik are pointing out that you may have two issues going on:

- Torch is being compromised by the way it is attached to the z-axis, and

- Pierce delay is not sufficient to pierce the plate completely and perform adequate cut.

You are likely to have issues with the pierce delay even with the torch mounted correctly. If you do, you need to increase your Pierce delay. You will be able to see if the pierce delay is an issue as there will be all sorts of angularly spraying sparks. Once the plate is pierced, they are directed downward, mostly. If you see the torch moving and the angular spray is occurring: increase the pierce delay.

Thank you! I didnt even realize i had it mounted wrong

Im only having an issue with the pierce delay on the first cut of the path. After the first hole, the rest of the program runs great. This happens every program i load (18ga i have set to .4 sec - 1/4" i have set to 1 sec)

PD should be at least .8 for the cut60 on the Pro. anything lower and you’ll get inconsistent firing.

There is an inherent delay from when commanded to fire to when it actually fires and its about .5 secs.

I’ve seen some people get away with .7 secs but nothing lower.

Also set you air to 65PSI flow on the gauge with a machine torch and the plasma cutter will work better

There are moving parts inside the torch head. If it is clamped to tight it could affect the torches’ ability function properly/fire and you will ruin your torch.

TY for the reminder…I’ll change mine too!