Is there any good way to determine what speed I should be cutting at? I am getting a lot of slag and some areas that do not cut all the way through. Common since tells me I’m cutting too fast but having the same issue when I slow it down???

Cutting 16 gauge

What machine are you using, what is the voltage, 120 or 240? What is your AMP setting on the plasma cutter?

What I’ve noticed on mine using the everlast 52i on 240 volt cutting 14g. Optimal speed for clean lines and little slag is 75-125 ipm, and about 35-40 amps. 125 ipm works on around 40 amps but any faster you’d need to crank up the amps closer to 50. I cut a nice clean cut using 50 amps on 3/16 at 60 ipm. It may have been a bit too much amp for the speed, but it worked.

I’m surprised you aren’t cutting at 16g steel. Make sure your cutting distance/ cut height is at .058-.060 in the tools library I am finding a 0.058 is much better than the higher limit. Pierce height .15

Its all about the settings. Amps and Speed. I was experimenting with smaller tips at a lower amp with thin metal. I had various results.

1 Like

Thank you.

Using razor weld cut45 @ 240V

@CBritton76

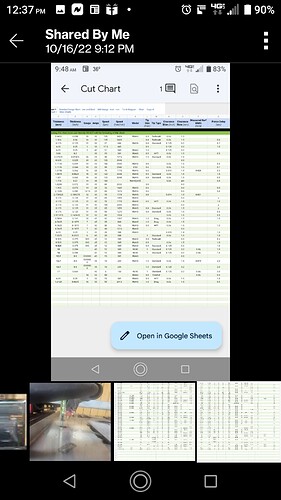

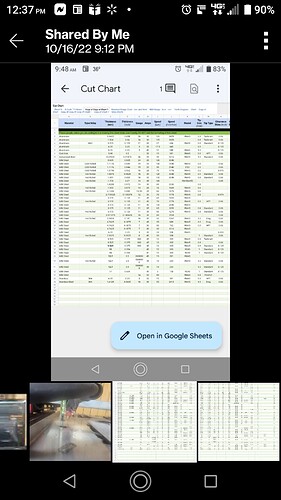

This is the best I can do I have lost the actual file. You should be able to line to two up and get all the information

These are only starting points

1 Like