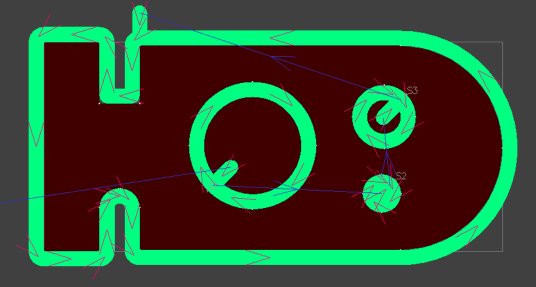

Here is the cut path:

I don’t have replacement consumables yet but doubt I have more than 30 min on the one nozzle.

BTW the part is about 1.8" long.

Is a 25 ft 3/8 hose OK?

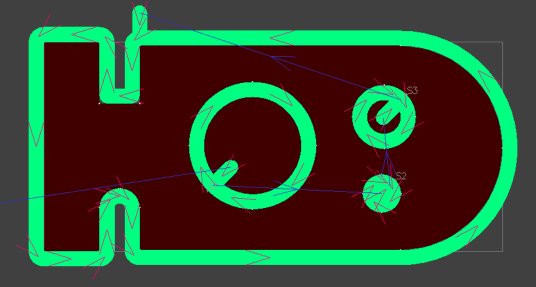

Here is the cut path:

I don’t have replacement consumables yet but doubt I have more than 30 min on the one nozzle.

BTW the part is about 1.8" long.

Is a 25 ft 3/8 hose OK?

@swisscheese Your cut direction is backwards.

Incorrect settings or wet air could easily toast a set of consumables in that amount of time.

What are you doing to control the moisture in your airstream?

edit. i see

Like @ds690 said this is not adequate.

@swisscheese BTW Welcome to the forum.

post pic of electrode

So far I only have the tip that came with the unit.

I also have desiccant now and waiting for more drying devices on order. “Welcome” - thanks ![]()

The missing, and usually ‘telling’, element is the Electrode. Fixing the nozzle is pointless if the electrode is shot.

Issue break down…

80% consumables

15% moisture causing consumables

4% speed and amps but once you get it figured out it’s not an issue.

1% something else like time for new plasma cutter.

Your not first with this kind of issue if you want to search this forum you’ll get all kinds of great information from start to finish.

Thanks for the good summary. Can someone explain why LS recommends only 220V - I’m using 115V and 1/16" standoff so far - just because the 220V outlet is not convenient. What would be the equivalent standoff for 220V? BTW I’m getting a taper of about 25 deg if that indicates anything (measuring angle of one edge vs 0 = ideal).

115v or 22v volt makes no differance on the stand off…what the voltage differance does is limit your cut time.

check the specs on your plasma you will find you can cut around half the time on 115 vs 220…

a 25degree taper sounds like your consumables are shot…nothing you can do to fix that other than replace the consumables…

If you are still using the drag shield that is 90 percent of you issues. You can’t use the correct cut height unless it is dragging on the material. That alone will cause trashed consumables and bad cuts.

Cutting tip and electrode both need to be replaced, they are toast.

You need to get some new consumables.