i started cutting a file with the persons name and a date part of the letters cut but others just do a pierce and stops i adjusted the pierce delay and ran from another loop it cut fine could the lettering be to small

anyone have a suggestion this a new problem for me

did you try simulating a cut in the cam software? if so did it show everything cutting?

@Knick asked some good clarifying questions.

From our standpoint we would not be able to answer if your lettering is too small. Perhaps you are trying to keep the message on your part private. In that case, mock up another sketch with the same size lettering. If the simulation works maybe that gives you some clues for your other piece. If it doesn’t work, then you could share your DXF file and we have something that will help us understand what you are dealing with.

And you confused me with:

Are you saying the entire piece cut “fine” including the small letters?

No I didn’t try that I’ll look at it when I’m back in the shop I just don’t know why it will cut out the other areas and some of the lettering then it will only do a Pierce and stops I changed the font and enlarged the size and spacing of it still same problem

Assumptions:

- Work clamp is on the metal

- Plasma cutter is not starving for air

- You have cut something successful, recently

- The torch cut height is good, not too high

- There is no warnings on the plasma cutter

- Consumables are in good condition

- No other cables are touching the USB cable

- No recent changes of you setup from a previous successful cut

- Dry air

Information that would be helpful:

- Plasma cutter you are using

- Gcode is from Fusion or SheetCam

- Many people with Hypertherm are reporting higher than usual torch heights during cutting (you are not having this problem?)

- Pierce delay, cut height

- DXF file

- MACH3 or FireControl

- Langmuir table: crossfire, pro or XR

- THC or not

- Laptop plugged in or on battery during cut

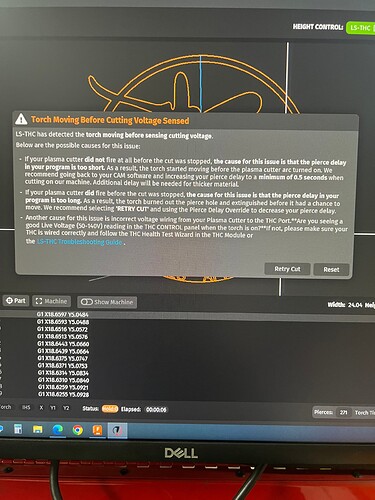

im using razorweld45 on crossfire pro with fusion 360 and firecontrol with thc pierce delay is at .5 and cut height .063 i ran simulation and it done fine i can cut most of the lettering and all the out line fine it will randomly stop and error comes up that i lost voltage during cut

type or paste code here

i ran the manual torch fire and i dont show live voltage which i dont understand it looks like it wouldnt cut anything without live voltage

I would try increasing the pierce delay to .6 or even .7 seconds. Realize that the first pierce always has an additional delay built in. Without redoing your gcode, you could have FireControl increase the pierce delay: try increasing by 15 or 20% so that would be 115% or 120%.

I have Hypertherm so I have to set it at a minimum of 0.64 seconds or I get that message a lot if it is anything less. I am thinking I need to go to about 0.67 seconds.

I am not entirely sure that FireControl monitors the voltage during manual firing so it probably won’t show any voltage.

ok ill give that a try i watched the voltage on the first pierce it goes to 2.8 does that seem low

i changed the pierce delay but that didnt help i did run the test and shows i no live voltage so im guess i have something wrong with the cutter or the vim box getting a little frustrated at this point thanks for the help so far

Don’t let it get you down. You know the night is always darkest just before dawn.

it is more than likely in the vim have double checked wiring? You could have a short in your wiring. you should see well over 100 volts in most cases.

there is a flow chart posted on here with step by step troubleshooting.

This might be what Phillip is referencing. Check at the bottom, below the flow chart. There are photos and testing for the VIM.

This is additional text that was on the post from langmuir on another topic:

![]()

![|25x25]

You could always work your way from the plasma cutter to the THC output barrel connector with a multimeter and make sure your voltage falls within the expected ranges, 1.2-3V at the cutter, then that number multiplied by .685, as the VIM further reduces the voltage 73:1. Figure out where the issue is stemming from and we can aid with the resolution. Feel free to review the THC troubleshooting guide for additional information.

Thanks I’ll start diagnosing it tomorrow hopefully it’s nothing major

In either case, you might start a ticket to Langmuir support. They will want you to explore as much as possible but if you get hung up, reach out to them.

https://www.langmuirsystems.com/support

Update on I my problem I went through the flow chart and it came to showing I needed a usb voltage isolator has anyone had to put one on their machine and did it actually work

Langmuir has noted a few times that they have sent them out. And, the one note mentioned that they supplied it for free. I cannot guarantee that is still their policy.

Report your issue to the help line and see what happens.

Yeah if you’re using a cable without any ferrite chokes you definitely need them. I’ve been using a very long cable with additional chokes on it for a while with no interference issues. It’s even coiled right now among countless other wires and my machine works as designed. K could shorten it with my current configuration; but I see no need.

Good morning everyone a little update on my losing voltage I’ve been talking with Langmuir but we haven’t been able to narrow it down yet but we did figure out that I don’t have enough air supply coming out of the Razorweld no matter how high I raise pressure at the regulator I only get 60-65 psi out of the plasma has anyone had this problem with their Razorweld plasma Langmuir wants me to get this issue fixed before we try to resolve the loss of voltage issues it seems like when it rains it pours in my world Thanks

You’re referring to the built-in regulator located inside the RW45? If it’s under warranty, then you should be able to get the RW replaced, just contact their support. If you’re no longer within warranty, you can take the built-in regulator out and bypass it with a short pipe nipple in its place. You should have a regulator installed off the back of the RW so you have better control anyway - it’s a PITA to fuss with the built-in one anyway ![]()