So I’ve been using crossfire xr for about two weeks now. It’s been a game changer for making brackets, tables, washers even. But I am having huge problems with lettering in fusion 360. No problem making a complex bracket with 50 holes, but lettering just doesn’t work. I write the text, (both stencil and regular) and explode it, send it to manufacturing and try and contour it. It contours and even though half the time it takes me multiple attempts to get the arrows facing the right way I get it, click ok and wait for the tool path. Well every time it skips random letters entirely. If there are 3 letters it skips 1. If there are 50 letters it skips 6-7 random ones. This only happens with letters, not holes, lines, boxes. This is maddening, any help would be greatly appreciated.

Thanks,

Christian

I am sure someone with more knowledge will be along with the answer.

Are you placing the leadin position or letting f360 do it? How wide are the letters? Does the leadin fit?

Is the part extruded? Extruding helps f360 identify what side the cut should be on for holes…

Also. Iv had issues with open path after exploding letters.

Can you post your F3D file that is giving you trouble?

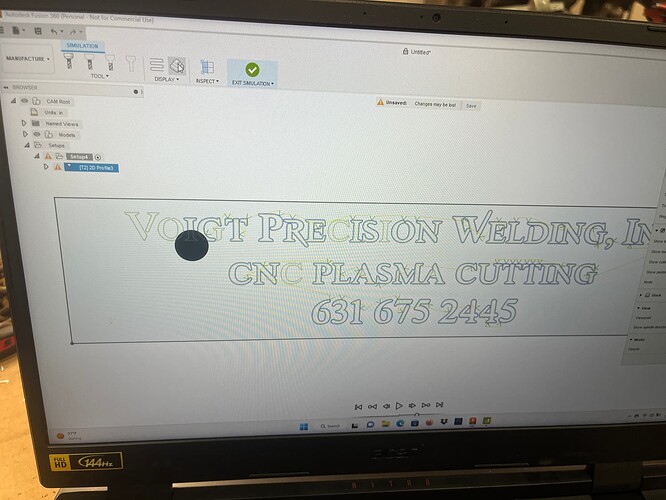

I deleted it already. But I took a screenshot. I know the contours are on the wrong side that was me seeing if that made a difference. My laptop is at work I’ll try again tomorrow and post it.

Kerf width vs letter dimensions are usually my issue. I have sometimes had to just delete a letter and replace it.

As far as fighting with those arrows, are you using the “Always…” option? That can minimize frustration.

So I think it’s a combination of a lot of things, font styles, lead in amount. I set the lead ins to .06, changed fonts, and placed the lead ins as best I could and it helped a lot, I got it to work on 1.25” tall letters, I was hoping for 1” but probably need a blockier font I assume.

Yes I tried always and it skipped over letters, I think I’m getting there now… lots of trial and error

Not sure of the scale, but that looks really good. Even the punctuation (",", and “.”) look crisp.

What were your steps to get to this improvement?

Honestly not entirely sure, I changed a lot of variables. I’m certainly amazed how well this cuts though, I’m running an everlast 82i, 50 amps 88 ipm. There is literally no dross, just a little at each pierce. I changed lead ins, font, and also saved the program, closed 360, opened it and then generated a toolpath and it doesn’t skip by doing that. Im just amazed by the cut quality.