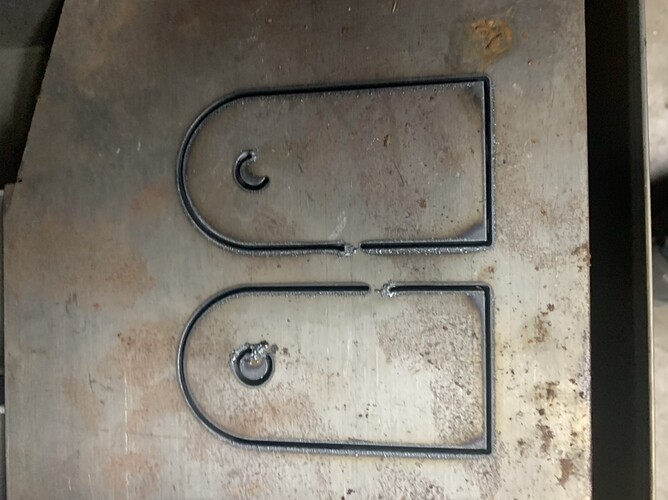

These tabs are not in the program no matter what I do I cannot get rid of them here’s a photo

increase your pierce delay. looks like its moving the torch before it starts to cut.

I override the piercing delay by 500% it didn’t get better and then I override it to go to 10% and it got worse. what kind of live voltage should I be seeing?

It seems like there’s quite a bit of delay in the plasma cutter firing.

what’s your pierce height and cut height set to?

if you can see the torch moving before it fires and starts cutting then your pierce delay is too low. what is it set to now?

It’s set at 0.05 Pierced delay and .060 Torch height. I have Torch height control. I was reading in another thread that the voltage 50-1 voltage divide in Everlast plasma cutters create problems people are saying to switch to Raw voltage

0.05 is probably way too short. What thickness material are you cutting? I’m usually in the 0.5 to 0.7 range pierce delay. Hypertherm cut tables probably can get you in the ballpark even with a different machine.

Several things can create this. Believe it or not. check all your lead screws and motors etc. Everything that moves. If it is loose it will create problems. Even worn bearings will create small tabs.

-

Make sure you are cutting clockwise on outter pieces. also good ground

-

make sure pierce delay is right and you can add a little bit of overcut in sheetcam.

-

I have no desire to comment on everlast. I used a 50amp for a couple days and absolutely hated it.

As turbo454 mentioned, your pierce delay is way too short. start with .5 and adjust from there.