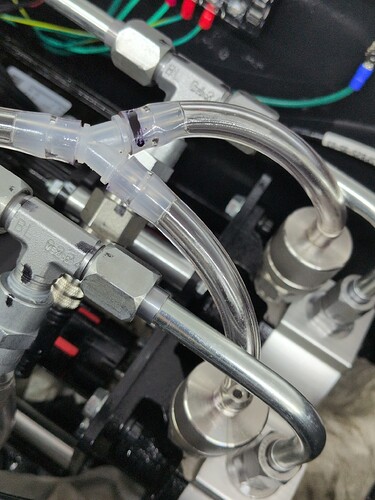

Anyone have the fittings on the clear hoses leak? Someone posted a pic of the same fittings leaking but I cant find it to see what they did to fix it.

I have never ran across a fitting like this before

There should not be oil those lines during normal operation so if need be, you could unplug the lines to drain them and plug them back in. Are the tops of your pressure relief valves wet or is the area below the valve wet?

If it is only the area below the valve then that is a leak thorough the threads of the valve - something you can fix with some Teflon tape.

- Mark down the current alignment of the upper valve body with the base 1" nut - if there is not one already, draw a sharpie line on the 1" nut and the upper valve body so you know how they are currently set.

-

Twist the jam nut downwards to loosen it, and then twist the upper valve body an eighth turn (45 degrees at MOST) turn upwards to loosen it - no further than that. If you try to unscrew the upper valve body all the way it can shoot upwards on the spring and cause quite the mess.

-

Wrap the threads with 2-3 extra layers of teflon tape.

- Twist the upper valve body back to its original location so that your sharpie mark on the upper valve body lines up with the lower 1" nut sharpie mark again. Twist the jam nut upwards to tighten it against the upper valve body.

I already moved the upper valve body a little maybe 5-10 degrees. Both jam nuts were loose.

I will try and clean things up and try tape. How is that designed to not leak? I take it tape is not how they originally planned it

It’s just plumbers tape. Pretty mandatory for thread-seal joints. Sometimes our production line just doesn’t apply enough.

I had them blow off during a bend, I added zip ties on the tube but under the flared end of the nipple so the tube couldnt slip off. I have not tried to bend something that large since then so I cant tell you whether it was the resolve

Next time you run a high-tonnage bend, take a video of the Live Report Screen and send it to me. Support@langmuirsystems.com There may be some improvements we can make next time.

I appreciate that but I was actually over clocking the machine. I went by a list on the FAQ section of the ordering screen, of the metal thickness and widths that the machine can bend, and I found that 1/4" steel by 25"w was way too much for the machine to handle. After making many relief cuts it was still under the 20" the FAQ said was the max. I really dont think that I will ever need to bend a piece like that again.

The major design flaw is that TWO 1/4” high pressure blow off valves are going into ONE 1/4” TEE fitting…which further restricts down to 1/8” ID fitting into the tank…. 1/2 combined high pressure into 1/8” fitting IS GOING TO LEAK or BLOW THE LINES OFF ‘when’ the valves pop off because a stop, limit switch or soft limit in the software WAS NEVER INSTALLED on the bottom stroke…..![]()

THE PROPER FIX WHICH SHOULD BE COMPLETED BEFORE ANYMORE MACHINES GET SHIPPED : run each individual popoff relief hose into their own fitting in the tank. removing the vent port to the tank gets you an extra port. The vent is not required because the lid on the tank is not even close to being sealed in the first place and leaks oil everywhere anyways with all the silicone pressed out of the gap is was supposed be the seal..

Wow! My condolences - I understand cleaning up a mess like that is a huge pain. Let me know if I can send anything to help you out.

It really looks like you managed to bottom out the machine hard. Ideally, those lines should never be blown or even used during normal operation, and especially not with that much force. Perhaps your PRVs need a little bit of a calibration increase so the machine properly stops before spewing out so much oil. Most pressure blow-offs have far far less oil coming out of them. I guess this is the equivalent of your car’s airbags making a mess when they are deployed. We don’t want the airbags to go off in the first place and the mess is better than the alternative.

In terms of design solutions, if you think that is likely to happen, then the full fix would just be to rout those lines outside of the machine into a big bottle. In operation a blow-off like this is very rare and I don’t get many comments from customers about it.

I am curious, what caused this? Was it a full bottoming out of the machine? Or an attempt at a high tonnage bend?

I have had this happen a few times as well if you make a mistake selecting tooling. I initially had quite a few problems with my machine so I’m quite adept and comfortable taking it apart. I added a second return line to the tank so each valve has its own return line and used a bit of stainless wire wrapped around the hose behind the barbs and twisted tight. I haven’t had a problem with it since.