We just got our new pro table up and running. I’m using sheetcam Hypotherm 45, 22 gage metal. We’re having issues on all gauges and settings getting clean cuts. Where the cut starts it leaves little holes. Can anyone help? I believe our setting are correct in sheet cam for our tool of choice. Can’t seem to adjust leadin in Sheet cam so we don’t get the holes at start.

It is great to see people who get off to a decent start and things are not that bad…

please do not take offence to this…but this is a classic example of trying to run before you can walk…

You have done a great job with the design and setting up mostly the right parameters…but going all out before you get used to the settings can waste a lot of material.

22ga metal

hypotherm 45

what amps are you set at?

what speed is the torch set at IPM?

when setting up in sheetcam…Operation…Plasma cut…

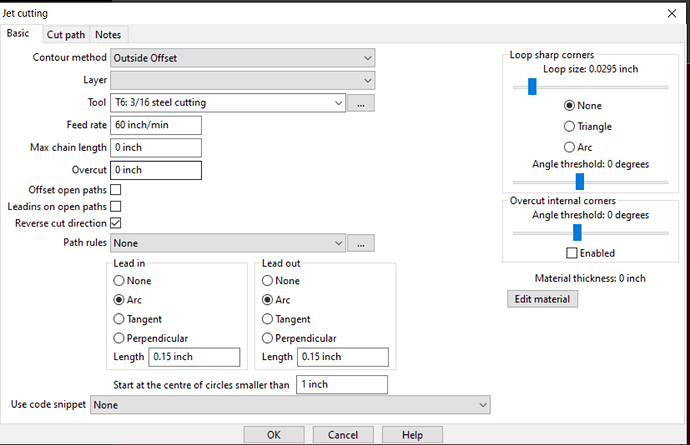

you get this screen

this is where you adjust for contour method…inside offset…inside offset…no offset…

you also need to set lead in and lead out…

when you set your tools up that is where you set your tool speed and pierce delay…

all this will eliminate the little holes…

from what I see…you are set on outside offset…and should be on inside offset…

your speed seems slow as you have a little warping…

your pierce delay is also a little long as well as possibly your plunge rate…

With 22 gauge you should be on fine cut consumables as well.

We’re using fine cut consumables, we had the older table and just upgraded to the pro. I’m using the same tools from old table. Our hypertherm book doesnt seem to say plunge unless they call it something else. Is plunge the ‘torch to work distance’. I can update my tools if that’s the case.

Any help is appreciated.

We’ve also changed our offset to each one and the results are the same.

All of the cuts shown in your picture should be inside offset, which will pierce inside the line and leave the pierce and lead in cut on the waste piece. They are clearly set to outside offset in that picture. Sheetcam usually can correctly determine which loops should be inside/outside/no offset and do that for you in a single operation. If there is a problem with broken lines in your file, Sheetcam will not be able to correctly determine what the offset should be. When you import the drawing, Sheetcam will show the outside offset cuts in Red, inside offset cuts in Yellow and open paths in White. If it doesn’t show correctly, you probably have broken lines/paths. In that case, you can fix the file or simply move all of the inside offset cuts to a different layer and create an inside offset operation for that layer.

I’ve just gotten up and running (only made 4 cuts so far) so I’m no expert, but it looks like your lead in is on the wrong side.

In other words your inner holes are set up as outer perimeter cuts.

Also, “plunge rate” is the speed that the torch moves from pierce height to cut height, after the pierce delay. The default Sheetcam setting is just over 3 inches per minute, which is way too slow. It should be set to at least 50 ipm.

Thank you. I’ve been reading a lot of blogs on this and everyone seems to do it a bit different. I’ve read use 1/2 of speed measurement. We will make some changes and dial things in.