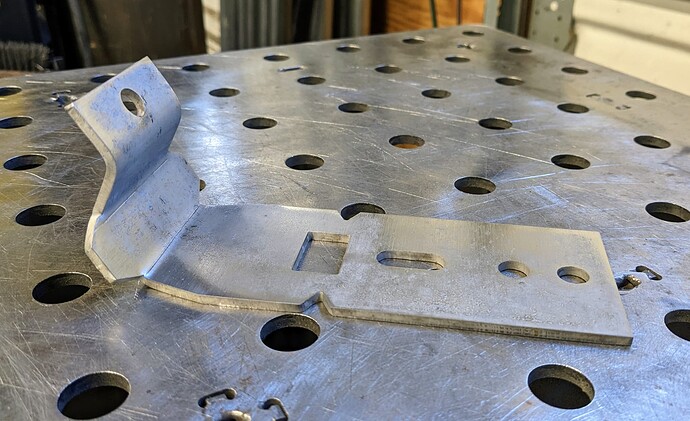

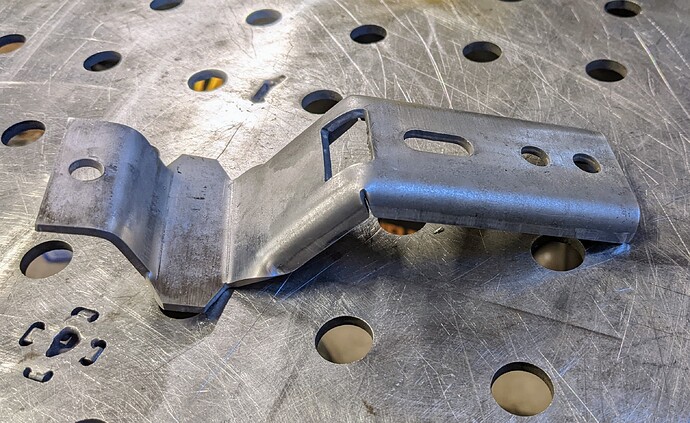

I make these discontinued Jeep YJ tailpipe hangers 5 or 6 at a time and sell them on eBay. These are some photos of the steps to produce the large part of the hanger.

Nice looking parts.

Thanks. I just stumbled into this YJ exhaust thing, because a friend needed one and couldn’t find it anywhere.

Is that some type of finish on those?

It’s a one step phosphoric acid solution that creates an iron phosphate layer to resist rusting. I wish I could get more if it, but the company doesn’t sell it any more.

A regular phosphoric acid solution does the same thing, but it needs to be rinsed immediately and then dried to prevent flash rusting.

That flash rust is just cosmetic and doesn’t matter under paint or powder, but it doesn’t look good on bare metal parts.

I use iron phosphate, but always put a finish over it and I do get some flash rusting but not very much.

I have never tried but I wonder if you were to use iron phosphate and then soak in a mix of water and baking soda if that would work. I do that after soaking in vinegar and i am amazed at long stuff can sit around without rusting.

I just rinse my vinegar soaked parts with plain water and dry them. I have some parts sitting my shop for over a year with no rust on them.

I might experiment with the baking soda rinse and phosphoric acid. The One Step IP stuff that I have is nice, because you just dip the parts and hang them to air dry. It has some type of cleaner and also some type of salts that fall out of solution over time and need to be stirred back up before use.

What kind of brake do you use to do the bends?

It’s a combination of things to achieve that shape. The first 3 bends are done on a harbor freight 36" brake. The sides get folded in a fixture that I made for a 20 ton press. The two small tabs get bent with an adjustable wrench, while the part is clamped in the bench vise.

I tried to upload some pics of the fixture for the 20ton press, but the forum doesn’t like the file extensions today.

Ive got a barrel with a piece of steel plate welded to the top that now sits outside and I’ve sprayed the iron phosphate on the plate and didn’t rinse off just to see what happens and the areas I sprayed have turned black whereas the other areas have continued to rust…

Wow anytime i pull parts from vinegar and don’t soak in baking soda they flash rust bad.

Very nice work, professional looking.