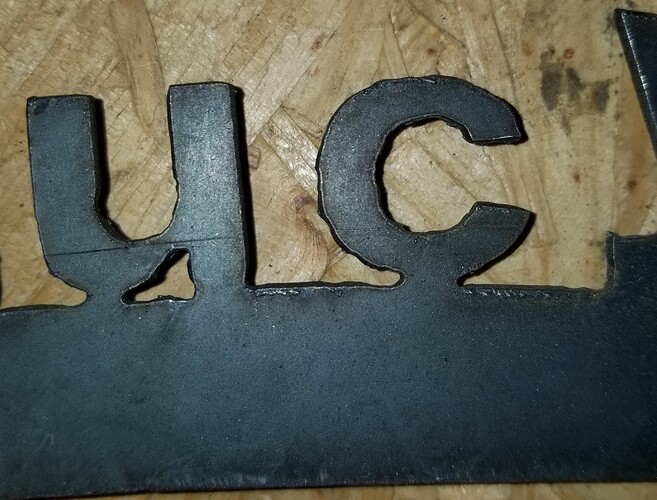

Hello I having an issue when i cut letters and some curves I have a jagged edge finish. I do not think it is a progam issue but I am using Fusion to pick the font, this case it is Arial Black, bold. I then use sheet cam to write the g code and cut it in Mach3. I have a hypertherm 85 but I turned it to 45 and cut with a 150 ipm. I have changed font and used an old design that I cut a few months ago fine but now gives me that edged cut. Any thoughts on how to fix this. Thank you

I’d try new consumables first and see how that goes. Check all stepper motor mounts to make sure they are tight.

Is your cut file from an image thats been converted, like a silhouette? A lot of times if I convert a silhouette to an svg and create a cut file the cut path is literally hundreds of lines and the torch will be very jerky and not accelerate smoothly. So the rare times it happens I go into mach3 config and change the read ahead from 20 lines to 50 and it gets real smooth.

I too am suddenly getting some jagged cuts (Crossfire with Prime Weld and PTM-60 Machine Torch). Can’t account for it yet, X, Y and Z axes are rigid, lead-screw fixings are tight, everything seems snug, but jagged cuts come on intermittently, on both axes. Hoping it’s consumables, but then again those were changed not too long ago. Will tear into it this weekend.

Here I go answering my own question. Changed the consumables and it’s fine again. I like doing the forensics, so here is what I’m finding in the old consumables, definitely some kind of wonky arc thing was going on inside there.

Good Camera!

El-Cheapo Digital Microscope

The arcing is from the pilot arc every time you fire the torch. You can stop some of this buy rotating the cutting tip. The lines on the electrode is most likely from water in the air.

Thanks George. My air is very dry. I believe one day last week, the torch got dunked in the water by accident, that would certainly account for it.