Were you successful with the 3D printed mandrels bending square tubing?

Negative, simply too much compression required on 1 inch tube. Only got 4 inches of curve from flat on an 82" length before the dies were done. The 3D printed dies would develop stress cracks each roll. I did remodel to use machine screws for connections, but that location would slowly bulge and deform the plastic die. Ordered dies from SWAG and finished up the tube rolling.

Steel vs Plastic

Steel for the win!

Do you think using a different type of filament would have made a difference?

I’d love to know more about how this was assembled.

I’ve done a few stand off type signs and some of them I’ll weld on a stainless nut on the front most part and then thread in a screw from the back. I’ve been thinking of just gang drilling through both, and welding in a stand off, but then how does one get paint onto the backside of the front most layer.

Maybe it’s best powder coated?

It was either a stud welded to the front peice with a nut as a spacer or a bolt glued to the front. I can remember which. If you look closely you can see the nut on the left and right sides.

Looks great!

It would require more testing than I wish to pursue. Plenty youtube videos showing strength tests of different filaments but this use case is such an extreme, I don’t think any filament would survive rolling a 1" tube. Thin flat bar requires much less force.

These guys successfully made tubing bender dies in a similar fashion.

Maybe roller dies like these would work.

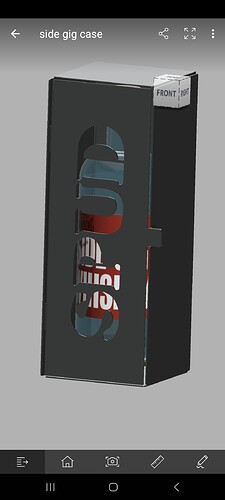

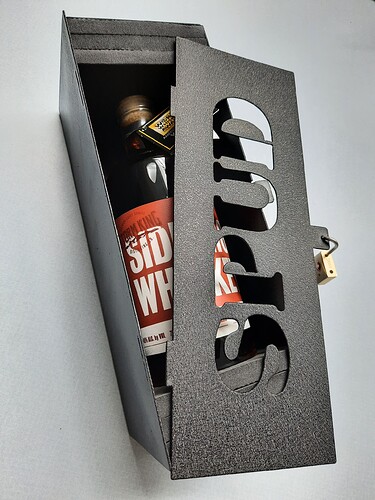

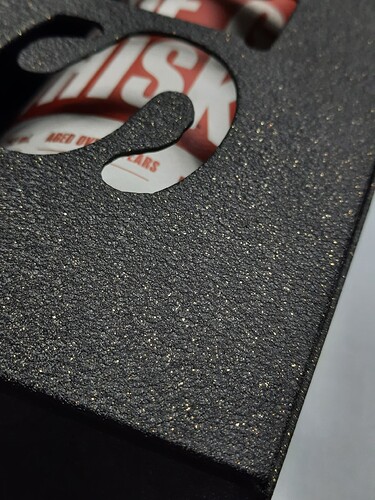

Last February a local distillery here, Stormking, was awarded the “Best American Whiskey” at the 2023 World Whiskies Awards. Batch 8 came in yesterday and I got one for a high school friend who just retired ( we call ourselves Spuds ). Made him a custom Side Gig lock box. 2 CAD hrs, 5 Fab hrs, I’m starting to get fthe hang of this. Life is good, have a great week.

Powder Columbia Coating Gold Ore

Nice box for the Whiskey! Good that is has a lock on it. But that begs the question, WHO gets the key? ![]()

Now that’s a good question. Unfortunately, this small lock is for luggage, so the TSA can open it. ![]()

So don’t put it in Check Baggage! ![]()

Now wife wants you to cut firewood! Looks very nice.

what is the thickness of the steel on that fire pit?

14ga. Most likely to thin but I got a ton of it .

I’ve been considering buying an X1 Carbon, would be my first 3D printer. How do you like it and would it be a good 3D printer for a first timer? I really like the 4 spool feed system and the LIDAR and shaping software, seems like a really complete machine. I wish it was a bit bigger but for a first machine as someone who doesn’t know squat about 3D printing it seems like it checks a lot of boxes.

GG, I’ve had several printers over the years. Purchased a X1C about a year ago with 2 AMS units. Its a wonderful printer and I haven’t had any issues with it. The slicer/sender software called, Bambu Studio, is easy to use even for beginners. Its open source with a vibrant fork existing called Ocraslicer. The phone app, Bambu Handy, is great for checking print progress. For me, it just works and I print now more than I ever have. Five of my friends have X1C with the same impressions. When you purchase one, make sure to order the textured PEI build plate. No glue stick, tape or whatever. Every first layer sticks to it and parts are easily removed. Cleans with iso and paper towel. I highly recommend and would buy one again without hesitation.

ps. I post my silly projects over at printables. Here’s my latest.

https://www.printables.com/model/576775-breville-bes870xl-portafilter-arbor-press-die

If you’re interested in spending a little less money, the new Bambu P1S is pretty much the same as the X1C, minus the lidar, in terms of performance. It’s still compatible with the AMS system and it comes with the high temp PEI build plate. It doesn’t have the hardened extruder gears or nozzle, but those can be swapped pretty inexpensively. If you’re not printing with carbon filaments, you don’t need the hardened parts.