Found this stuff by Rustoleum and I really love it.

In 24hrs it dries to a tough vinyl-like finish (smells like rubber). Here are two 16g plasma-cut specimens for my Land Rover, a Cup-holder and a Radio/Switch-panel (steel and alu respectively) coated with it.

Question: if you replace EVERY blooming part on the vehicle, is it the same vehicle???

Something to contemplate as we drool over the ‘thing’… ![]()

Answer: That’s why we were very careful, NOT to replace every “blooming” part ![]()

![]()

I would think that 1 or 2 screws from original frame does not count as minor rebuild…

Looking good Cletus, nice looking cup holder and switch panel as well.

Wow. Looking really nice. You’re really moving fast on that. Most folks undertaking a full resto of a car plan on it taking years.

Thanks guys!

I’ve contracted a couple guys with a small garage to do the major work. They are experts at Land Rovers and have a real passion (OCD) for it. Their price is EXTREMELY reasonable at US$5K including supplying all parts. The power-steering mod cost like US$500.00 additional. They’ve got maybe another two weeks work to do on it and they’re on budget. They’re out in the countryside, about 2 hours drive each way on bad roads, so i only go out there every other Sunday. I have some doctor friends interested in such also, so we’re looking for a couple more specimens to restore for them. Could turn into a nice little side hustle.

We also have the whole process from day one, photo and video documented for a YouTube presentation when it gets back on the road.

. ![]()

![]()

Amazing piece!

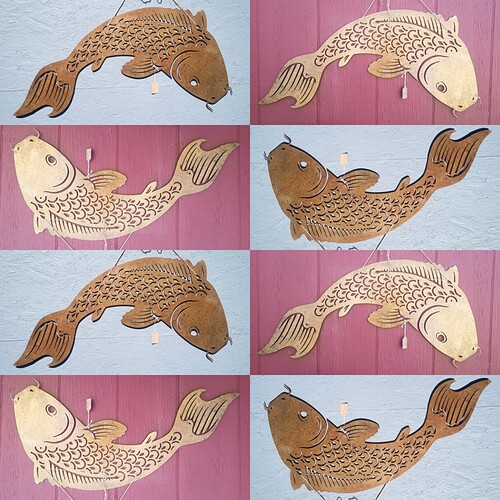

This is a large koi fish piece we cut it’s been up in the gallery for a while so I decided to take some pictures of it I’ve been the sun today.

Nice fish, but you spent WAY too much time in the Sun!

Always knew there was something “fishy” about @TinWhisperer

His Koi attempt at humor confirms it…

Main problem with Koi is they multiply so fast … even when hanging on a wall.

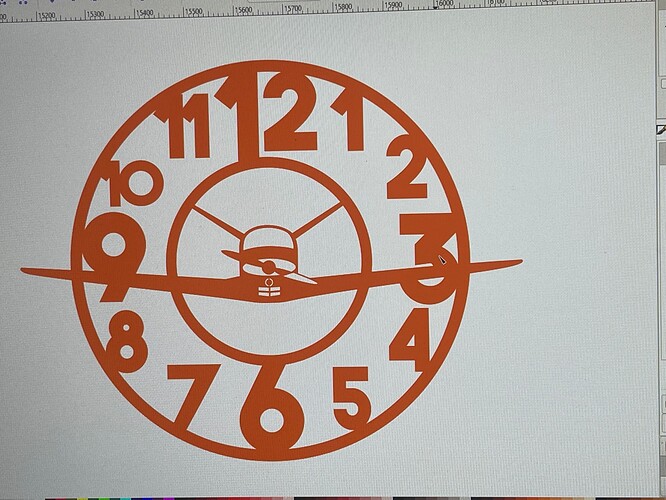

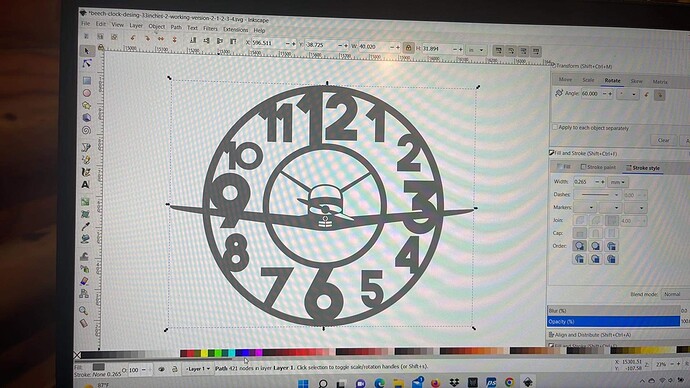

Nice. I like the clock design - the number design (font & size) is well matched to the size of the clock.

Beautiful welds!

I just did the normal internet search of large wall clocks.

And some cuts others had already done…

And got the idea for it from all those…

Wanted enough bridges / union to be throughout so it can be cut from thinner sheet and still be stable .

At .135” on this piece its pretty stout.

I have an aviation version I’m working on as well. Im thinking an LED backer maybe on this one.

Or just a offset back with welded spacers🤷♂️

Nice!!! …one day I will get around to doing a clock myself! ![]()