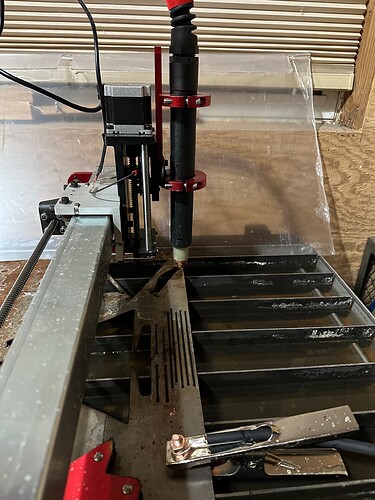

I bought my crossfire and cut 45 (with machine torch) in October of this year (2024) and have made a few items successfully (less than 15 minutes of cut time) but now I’m getting an issue with my plasma cutter where it will make the first cut in a file and after the torch move to the second cut the torch will not fire. I have to turn off the plasma and the cnc wait 3-5 minutes and then turn it back on again. I’ve tried everything I can find on this forum (this one seemed the most similar to my issue but none of the suggestions resolved my issue: Razorweld cut 45 issues (Solved) - CrossFire ® PRO / Troubleshooting - Langmuir Systems Forum). I re-ran the THC test (after the 3-5 minute reset) and the torch fired each time. I’ve tried a hand torch (after the 3-5 minute reset) and it also fired several times in a row. Here is a pics of my setup:

I’m sure this has nothing to do with the issue, but as a side note I would eliminate that extra regulator.

It is doing nothing for you other than being another item in the chain that can fail to deliver air reliably. Seen it firsthand for others.

Since it fired several times in a row with the hand torch, it’s probably not a plasma cutter issue.

It’s probably a pierce delay issue. It will always work on the first pierce, even if your delay is too short, but it won’t work in subsequent pierces.

What is your pierce delay in the program?

Can you copy and paste the first 10 lines of your G code into a post here?

I have the pierce delay set to .5 seconds. I would add that one of the tests I was doing was just using the manual line cutting in fire control to cut a line then move the x & y axis manually, reset to zero and try to cut another line. This simple test also fails to cut on the second cut.

Here is the G code snippet from one of my projects. Let me know if you need more:

G0X6.9336Y2.6388

G92Z0.

G38.2Z-5.F100.

G38.4Z0.5F20.

G92Z0.

G0Z0.04

G92Z0.

G0Z0.15

M3

G4P0.5

G0Z0.063

Pierce delay looks fine, but you need to set that springback value to zero.

oh ok. Do I set that in post? or is it in fire control? I’m using Fusion 360 if that helps.

tried the following G code and it cuts the circle but the torch won’t fire when it moves to cut the square. One thing I’d also note is that if I don’t wait 3-5 minutes after powering down the plasma the hand torch will also not fire. If I wait, then the hand torch will fire multiple times in a row. Here is the G code:

(v1.6-af)

(Machine)

( vendor: Razorweld)

( model: Cut45)

( description: Generic Cutting Machine)

G90 G94

G17

G20

H0

(2D Profile2)

G0 X0.9336 Y1.2331

G92 Z0.

G38.2 Z-5. F100.

G38.4 Z0.5 F20.

G92 Z0.

G0 Z0. (IHS Springback + Backlash)

G92 Z0.

G0 Z0.15 (Pierce Height)

M3

G4 P0.5

G0 Z0.063 (Cut Height)

H1

G1 X0.7942 Y1.3721 F100.

G3 X0.7094 Y1.372 I-0.0424 J-0.0425 F100.

G3 X1.3785 Y0.7047 I0.3346 J-0.3337

G3 X0.7094 Y1.372 I-0.3346 J0.3337

H0

M5

G0 Z1.

G0 X-0.2444 Y1.98

G92 Z0.

G38.2 Z-5. F100.

G38.4 Z0.5 F20.

G92 Z0.

G0 Z0. (IHS Springback + Backlash)

G92 Z0.

G0 Z0.15 (Pierce Height)

M3

G4 P0.5

G0 Z0.063 (Cut Height)

H1

G1 X-0.0475 F100.

G3 X0.0125 Y2.04 I0. J0.06

G2 X0.04 Y2.0675 I0.0275 J0.

G1 X2.04

G2 X2.0675 Y2.04 I0. J-0.0275

G1 Y0.04

G2 X2.04 Y0.0125 I-0.0275 J0.

G1 X0.04

G2 X0.0125 Y0.04 I0. J0.0275

G1 Y2.04

H0

M5

G0 Z1.

M30

(PS100)

Try cracking the cap on the torch loose. Not super loose, but just not tight. It might be compressing the swirl ring and restricting the movement of the electrode.

My guess he has a air problem. If you tighten a retaining cup down to deform a swirl ring then the swirl ring is bad and needs replaced.

Still no luck. Contacted Langmuir support and they think it is a bad plasma cutter. I’m inclined to agree since the hand torch also has the same issue if I don’t wait 3-5 minutes after the machine torch fails. I submitted a support request to jasic. We’ll see what they say.

Sounds like it is overheating, is the over temp light on? It doesn’t seem as though with the short cutting time that it would actually over heating. That being said, there’s probably a temperature sensor that is bad. Looking forward to seeing what Langmuir has to say.

If you are not getting an error in FireControl then I agree with George (air or electrode plunger issue).

Take out the consumables and inspect the torch for any o-rings you might see. Give them some silicone lubrication. Not too much. Check to see if there is any flat spots or cracks in the o-rings.