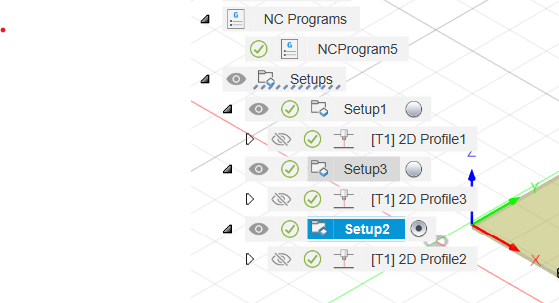

As far as Langmuir’s end goes, the crossfire pro and the Firecontrol software work beautifully, never an issue. but in fusion 360, at the machining stage, no matter what I fiddle with, I can’t seem to make the entire thing cut out. I always get at least one error that says that one or more parts has been discarded due to pathing constraints. When I change and try again, I usually can make it path the missing piece, but it always drops something else. I need someone smarter or more experienced to help me understand why this happens.

Kerf, and lead ins/outs.

Kerf value is the value (measured distance) of material loss that occurs when using a plasma cutter.

Having the appropriate value measured and entered in your tools, allows Fusion to automatically offset the actual cut path, to create a physically accurate product.

In other words, if you want a 2" x 2" square, the cut path itself will run at 2.04" x 2.04" (example) so the part physically measures as shown in CAD.

The other reason would be a lead in/out that is too large fit in a specific geometry.

I just did a Zoom meeting with someone earlier teaching them Fusion. I don’t mind doing another one today.

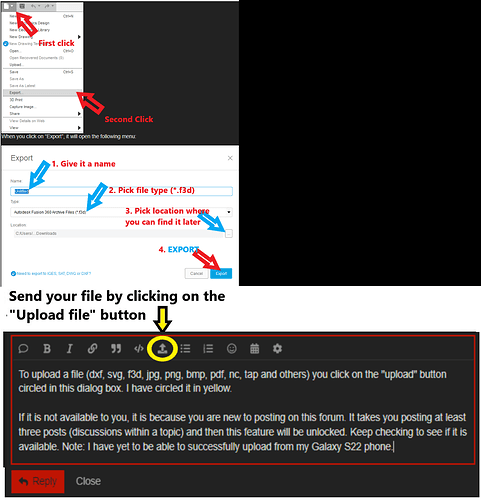

One of the best ways to learn is to share your f3d file here. One of us can look the file and tell you what is happening.

If you don’t want to show what you are working on, just mock up something that gives you the same error. We are truly not trying to find out what your design is. Most of us try to help sort of like problem solving and it helps us learn the program more.

If it is a really detailed Etsy type DXF file, those can really give fits with “Manufacturing.” And, that is a very poor way to learn Fusion 360.

@Martin20 Welcome to The Forum.

Ill get it uploaded now, they didnt allow me to upload files when i launched this

Going to piggyback a bit here as well to add that it could be overlapping lines as well. If you’re importing a DXF/SVG and creating a 2D profile from this it may be causing lines that overlap and fail in the same manner that @Kwikfab described too. Uploading a file or even a picture would help in determining what may be happening.