Hello,

Crossfire Pro, Razorweld 45

Working on a project that requires me to use 1/4" 6061 aluminum. Ive never had great luck cutting aluminum in the past, but trying to get the quality better. Ive also recently been having issues cutting thicker steel as well.

As far as settings I tried a variety all at 45 amps, and cut speeds ranging from 50 ipm up to 100 ipm, also trying different air pressure.

All results were pretty much the same, but had better luck with slower speeds and cutting with THC off.

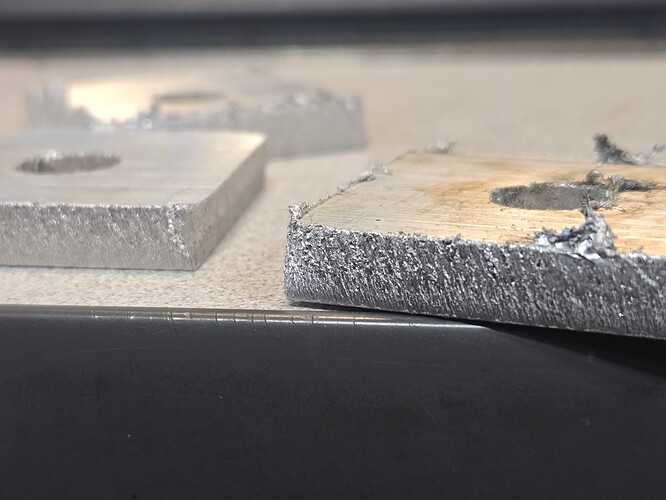

As seen below, I experienced tapered cuts even with verifying the torch was square to the work piece, holes out of round and when going around corners it tapered towards the middle of the piece.

Unsure which direction to go with fine tuning my settings and getting better quailty cuts. Later today im going to try new consumables. With pretty much any thicker material over 1/8" the THC is very inconsistent and notice it bobbing during cuts, which results in a jagged cut edge.

Any help is appreciated, even if its cut settings that have worked for you!

Thanks