Hi Burners,

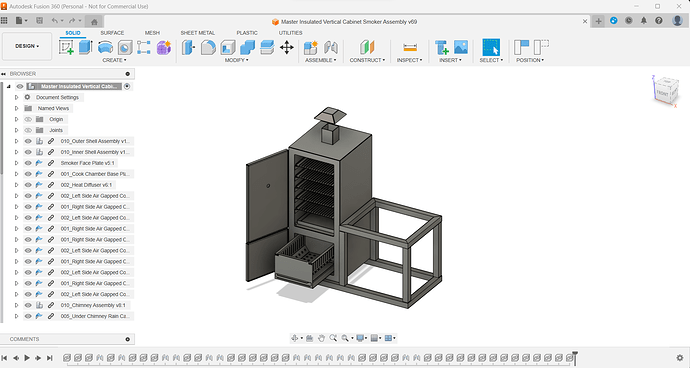

Sorry for falling off not too long after my entrance. I actually have not made a lot with my table since the last stuff I posted, but have been more involved in familiarizing myself with the design side on Fusion 360…

So here I am (yesterday) with 4 sheets of 1/8" that I am Looking to make pieces/parts out of. With the cutting that I have done so far, I have not had a single issue with the table, cutter, THC, limit switches, nada… Well, I probably got ahead of myself and went in too fast with my cutting I will admit, but now I’m in a bit of a pickle until I can get this resolved.

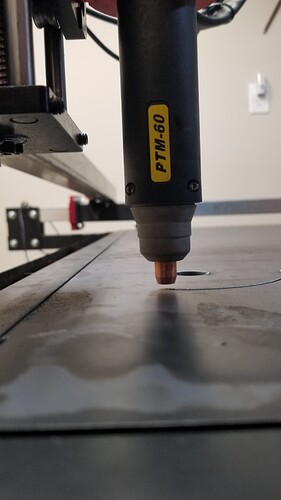

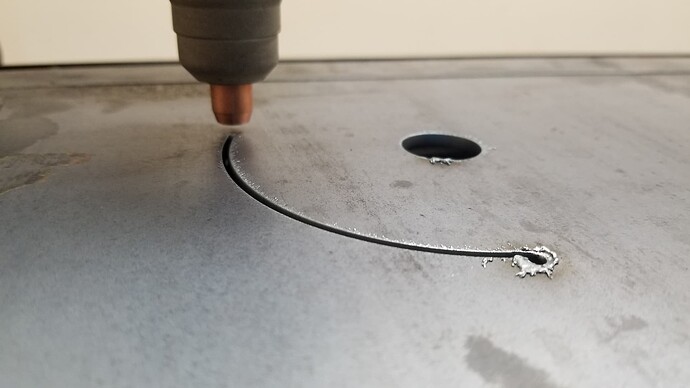

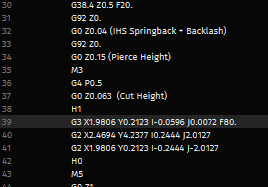

I start cutting one of my pieces/parts (40A, 86ipm, .06 standoff, 60psi at torch I believe when cutting), and it cuts out the first circle in a vented wall. Then it goes to cut the outer frame of the wall, and I notice that the torch appears to have a high standoff. Shortly after noticing, the arc goes out, fire control kicks an error message and I have an E04 error on my cutter. Baffled by this, I retry the cut and notice the same thing re standoff height. It cuts for a couple inches, then just gouges, then the electrode greened out on me as it was going bye bye. CRAP!

So I swap consumables, grind the mill scale at the ground attach point, test the spring in the torch, get lit up with sensing voltage ![]() and try again… Same thing each time. I am calling this failed attempt my drop section as it is still within range, so no harm/no fowl but I am curious if I am overlooking a path that has been gone down before? I realize that the E04 error is for overvoltage. I know that I have a good feel and good voltage going into the cutter. I really think that it is something else, but I am not 100% what it might be. I have read the few threads threads that I could find on E04 errors, and I plan on further inspecting the torch plunger and pins for free movement, adding a bit of silicone grease for future benefit…

and try again… Same thing each time. I am calling this failed attempt my drop section as it is still within range, so no harm/no fowl but I am curious if I am overlooking a path that has been gone down before? I realize that the E04 error is for overvoltage. I know that I have a good feel and good voltage going into the cutter. I really think that it is something else, but I am not 100% what it might be. I have read the few threads threads that I could find on E04 errors, and I plan on further inspecting the torch plunger and pins for free movement, adding a bit of silicone grease for future benefit…

I know that this is a little spastic wall of words, but curious: If my air pressure were to drop too low while cutting, would this be a symptom of that?

Project pic for reference. Will post more if I have any success at gitten her done…