X axis will not zero after running the breakin program. Pictures show where I set the x and y axis at 1/4 from stanchin and 1/4 in from bolt to set at zero. After the program runs you can see it does not end up in the same spot.

Did the break in program run normally? Do both X and Y seem off by approximately the same amount?

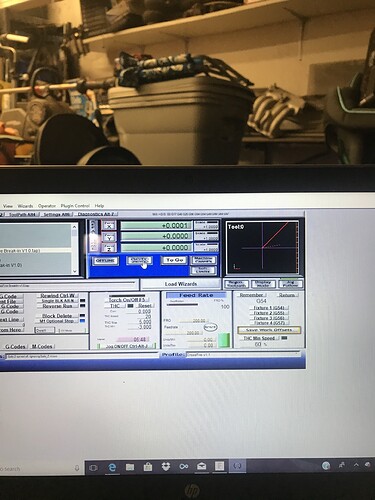

It’s just the x that won’t zero its is always .0001 off. The one pic I paused it and snapped a pic and it was off by the same amount still. After it runs it stopped in the spot that it started from but when I manually toggle it and then hit go to zero it went to the point in the picture which is about 1-1 1/2 inches from where zero was set

Yes the breakin ran normally. And I ran it two more times to verify and still get the same results

Make sure that your set screws are tight on the Lead Screws. I had a similar problem and that’s what it was. I ended up putting blue thread locker on all my set screws across the lead screws and haven’t had tat problem since.

I will double check them I made sure to tighten them cause I read that on the forum before I ever received my machine. Any other thoughts Langmuir. After the break in program is it supposed to set zero for x&y where you placed it and zeroed it before running the breakin program.

If you are talking coming to a stop X 0.001 off possession I see that as no issue 0.001"

Assuming all else is functioning go with it.

When I ran the break in profiles I had the same issue at this time I see it as no issue.

Will I change my mind later but unlikely.

I am referring to, I set the x&y a 1/4 inch from bolt and 1/4 inch from stanchin plate and after the program runs and I jog the machine then hit go to zero and it places it about a inch and a half from the bolt and inch and a half from the stanchin plate, wondering if it should go to where I set zero at before running the program. 1/4 inch from bolt and 1/4 inch from stanchin plate

It should go back to zero point physically. Yes it may (will) be off 0.0001 often, that is no big deal.

IF the table is not returning to visible zero, but the readout shows zero on mach 3, then you are losing steps within the physical stepper motor. This could be to the gantry bearings being too tight, or something else I am not aware of. At least that was my experience. Once I took the bearing assembly apart and readjusted, I had no further issues.

You may have some offset or incremental setting accidentally set on mach 3, if you are getting consistently wrong zero’s after running the program???

I’m not certain that its an issue with missing steps since the break in program ran multiple times without issue. If you were missing steps, you would have seen the carriage collide into the hard stops (and also hear the noise from the motors stalling).

To me, it seems like an issue with the go to zero function. Have you tried cutting anything out? If so, how do the parts look?

Excute me, but what is a thread locker? I am having some of the same issues I think…

read the label and instructions and make sure you get the right stuff…blue is removeable…red…well…you are out of luck

Im not sure I want to use that just yet… Im a bit afraid this might be another issue.

I agree with daniel that this is a go to zero issue not a physical slip or lost step issue. After reading several posts about coupler slip what I have done is marked the stepper motor shaft-coupler-lead screw location. I ran the break in program a couple times, each time checking to make sure I wasn’t getting any slipping with the couplers. I check them regularly to make sure i am not getting any physical slipping at the coupler.

Unfortunately with the expiration of Loctite’s patent, other companies have come out with threadlocker and muddied up the colors. Blue Loctite is now in a red tube (but called Blue 242) and is removable. It takes about 50ftlbs of torque to remove. Red Loctite threadlocker (Red 271) is also sold in a red tube but is labeled “High Strength”. You need to heat up the fastener to 500F to remove it. Once heated it comes off like it wasn’t ever on it.

BTW, there’s a green version that is used for nuts and bolts that are already fastened - it will seep into the connection and act like blue threadlocker. It’s good for when you forget to put it on before assembling the fastener or if it’s hard to get at and remove and you’re looking for some extra margin of safety.

sooooo confused…well lets say beyond normally confused

“zeroing” the x & y and “goto zero” are 2 different things.