I purchased the CrossFire with the XL kit to specifically make one product, bat house brackets that use 12 GA (.120"), but I did (and am doing) a lot of artsy fartsy things with 16 GA (.062") steel as well.

First, a BIG thank you to this forum, I know I don’t post a lot and that is mostly because with bit of searching, I find what I need has already been posted. So, thank you to all the contributors, in my opinion it is this forum that makes CrossFire line so valuable.

For budget reasons, I chose to use a plasma cutter I already have, a Northern Tool 375i 40Amp cutter. I had no problems setting it up or triggering it etc… it works well and I was told 40Amps was plenty. However, I strongly suspect this cutter is under performing the more I cut with it.

My first hint is how fast it can cut with good result. The air pressure is set to 60 psi.

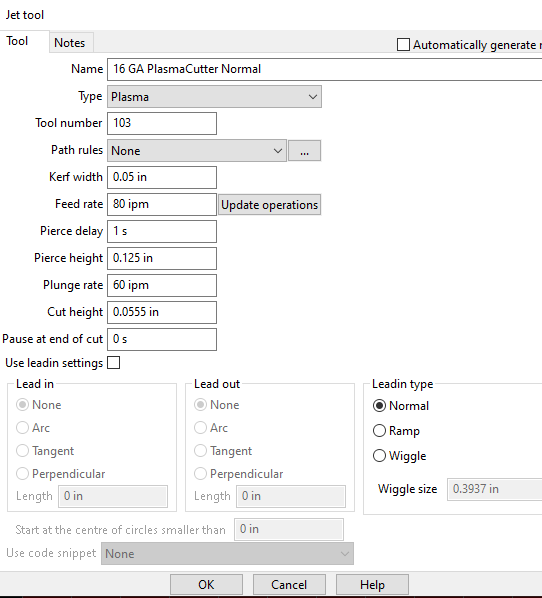

In 16GA (.062") I run at about 80 ipm on cut. I had expected that (based on reading) to be around 120 ipm (did I get that wrong?) But I used a coupon and was able to sneak up on 80 ipm, well here it is

If I stray to far from those settings, I get bad results.

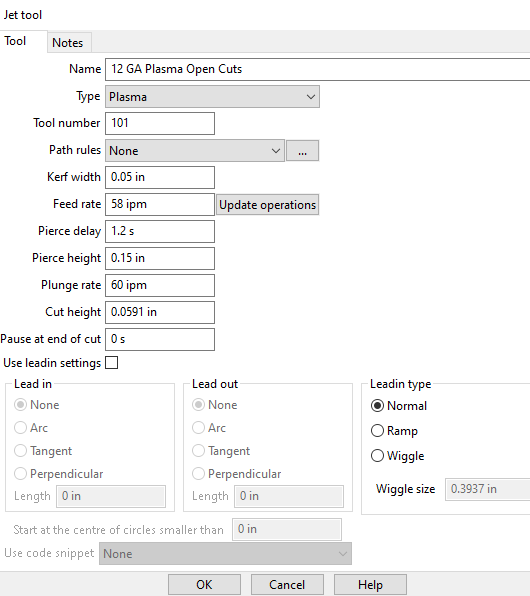

For the 12GA (.120") here are the settings, again with good results

That 58 ipm has some wiggle room, but anything over 60 ipm and it starts failing to cut all the way through as it speeds up. By the time I reach 70 ipm, it no longer cuts through. Again, compared to the forum information, that seems slow.

If that is all I wanted to cut, I would probably say C’est la vie and move on. But, when I move to 3/16" metal (actual is .20") I have to cut so slow to get through it heats the torch head and burns up the consumables more rapidly. If I move faster, it fails to cut through in places and leaves terrible dross. If I slow down to 40ipm for good cuts, it is moving so slow for corners and small holes that the plastic on the torch started smoking.

I tried 1 piece of 1/4", that’s not happening.

I’m thinking that dial that says “40 amps” is lying and it is actually putting out maybe 30 or less in reality.

In short, do I keep messing with this trying to figure out if I’m doing something wrong? Or is this just an under powered cutter and thus I’m asking too much from it?

When it cuts, it cuts well (albeit slower than expected) I couldn’t tune it any better, my 12GA material comes off very clean, any dross easly chips off (no grinding required) size is accurate etc…

EDIT:

I have tried grounding the table, the metal itself and both with little change

I have tried air pressure from 40 to 80 psi, 60 psi has seemed to do the best (this is according to the guage on the cutter itself. I’m feeding it with dry air at 120psi with a screw compressor that easily keeps up)