Hey guys! stoked to be apart of this community and start putting my CF Pro to work. I got it all wired up this evening and made some test cuts on a few brackets for the cable chains I added to it and am having a few issues with the consumables in my torch. Just for clarification my table does have the THC system and is connected to the raw voltage output in the CNC port on the cutter.

I bought a IPT60 machine torch for the cutter off ebay so that I could have a dedicated torch for the table and the other benefits of the machine torch. I bought the consumables from @mechanic416 ebay store, here’s the link to the ones I got.

For some reason when I cut with these consumables the results are just awful regardless of the settings I used. I sounds almost like the arc is weak and unstable like its sputtering. These were the best I was able to get with these consumables, I messed with every setting possible and noticed no real improvement.

After an hour of messing with this I decided to grab the set of new consumables out of my hand torch that came from Everlast and try them. Exact same settings as the shielded consumables and here’s the result. Absolutely flawless cuts that were nice and straight with virtually zero dross. This is the kinda cut quality I was expecting from the shielded consumables and is right on par with the hypertherm cnc cutters I have been around. The arc also sounded much more powerful with no sputtering like the shielded. Pictures in second post because the forum wont allow more than 2

Im no stranger to CNC plasma by any means, I’ve been running the Arclight Dynamics table at work for years with a hypertherm PM105 on all sorts of materials. There is a ton of info out there on these IPT torches that I can find and am really not sure why the shielded consumables are essentially useless. I was under the impression they were supposed to be the best for longevity and cut quality when doing machine cutting. Hoping that someone can give some insight into what may be going on here. And just for the sake of sharing here’s my table all setup, the Y axis cable chain will be getting a support rail underneath like the x axis once I build it and wrangle the wires better.

Messed with the table and cut settings a bunch more today this time on 1/4" steel plate. I was able to get the shielded consumables to produce a decent cut but right at the end switch back to the unshielded and with identical cut settings as you can see in the pictures its just night an day. The unshielded has virtually no dross and what’s there flakes off with a thumb where the shielded still produced a lot of difficult to remove dross. Very strange and I guess Ill just have to settle for the the unshielded consumables direct from everlast for now.

What is your torch height set at? shielded consumables need .060" from the tip to the work piece, not from the shield to the work piece. That will give you a .090" torch height way to high.

1 Like

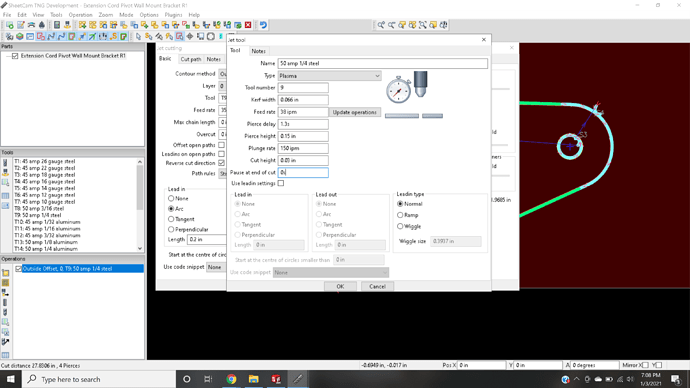

Here are my setting for 1/4" steel from the last cut in sheetcam. When I tried it on the 1/4" aluminum originally I had the torch height way tall due to the offset in the tip from the shield, didn’t realize that until this afternoon. I also tried a +/- 20% range of feed rate speed of that 38 ipm with no real improvement.

George, you may also be able to clear up some confusion I have with the razorweld torches, right now I am looking at this torch here from plasmadyne. It says its compatible with the hypertherm consumables and the razorweld consumable. Is this referring to the current style duramax consumables from hypertherm or the older style? Thinking of picking this torch up if it uses the duramax consumables since I am able to source those locally.

None of these torch’s use Hypertherm consumables (Hypertherm does not recommend using their consumables in any torch other then Hypertherm torch’s). If you want to use Hypertherm consumables then you need to buy a Hypertherm plasma cutter with a Hypertherm torch.

That torch does not use the 45XP consumables. It is a Chinese copy (along with everything else he sells), so Chinese copy’s of the old powermax 45 consumables should work on it. There is no real advantage to using Hypertherm consumables in a none Hypertherm torch on a none Hypertherm plasma cutter.

1 Like

Gotcha. I’ll just stick with the ipt60 torch then untill the table pays for itself enough to warrant a hypertherm machine.

Going to try bypassing the stock water trap on the plasma itself and run direct off my other filter system because I have a suspicion the filter is clogged up and that may be the issue. Lent the machine out maybe a month before I received the table and the bowl was full of water when it came back and it had never had moisture in it whatsoever before then.

The odds are if it has a brass filter in it its plugging up or is plugged up causing low air flow.

Here is a tidbit of info. They don’t tell you this in most manuals because the plasma cutter maker don’t sell them. But the filter in the onboard filter/water separator should be changed every 30 to 60 days.

Hypertherm does have this info in their manuals , but most people don’t change them anyway.

It does have a brass filter… Looking at it this morning it’s pretty dirty. Can’t seem to find a replacement element without replacing the whole dryer assembly so I’ll probably just delete it all together. I figure there’s not much need for it with my other filter system. Fingers crossed that it solves the issue

Well made a bunch more cuts tonight and it still just doesn’t seem right. Same sorta thing where the unshielded cuts great and shielded not so much. I did get the shielded to run consistently cutting all the way through a program by upping the air pressure to 75psi but there is still a ton of dross compared to the unshielded. Really drawing a blank here.

Removing the brass filter did help some as well but not the magic smoking gun like I expected. I did notice as well that on my thc readout the unshielded is running 76ish volts cutting and the shielded is around 51 despite being at the same cut height measured to the cutting tip.

Just curious, but how are you running your THC wires to the plasma? Are you using the cnc port or did you tap directly inside the machine? I’m running the same plasma cutter as you and was only seeing 50ish volts when using the cnc port. After running the wires directly inside the plasma to the torch lead and ground lead, I was getting 100ish volts (which is where is should be for optimum THC) I saw a significant difference when wiring it this way

I am wired into the raw voltage leads in the cnc port. I just actually ran a piece of 3/8 using your settings posted in another thread and unshielded consumables and got near identical results as you did.

Tried again with the shielded consumables and unless I reduced the feedrate by 40% it wouldn’t even pierce the plate. I will take a look at moving the voltage pickup inside the machine though, I would like to keep all connections isolated to the cnc plug but I could wire from the torch and ground lead back to the cnc port pretty easily.

Are you using shielded or unshielded on your machine?

EDIT

just got done rewiring the cnc port to reference direct from the torch and ground lugs at the front of the machine. test cut showed 110 volts in 1/4" steel

1 Like

I always use unshielded. I have honestly never tried shielded before. did you notice a difference now that your voltage reading is higher?

I didn’t really get to run a big enough file to tell very much but it did seem like it was a little more stable in its adjustments and not hunting as much.

I think for now I’m just going to run the unshielded and see how they do. No sense in beating my head against a wall trying to make the shielded work if I don’t need to.

1 Like

Send me a PM with your email address and I will refund your money for the shielded consumables.

That’s what I would do. When I was seeing the correct voltage, the torch was alot more steady when cutting, where as before with the cnc port, it seemed to Bob up and down when cutting

Roughly what kind of consumable life are you seeing with the unshielded in say 1/4" steel plate?

1 Like

I typically don’t cut 1/4" steel. Mainly 1/8" aluminum. I will get about an HR of cut Time out of a set before I start to notice a difference in cut quality. But aluminum tends to be a bit more messy to cut then steel as well, so maybe on steel they will last longer

Well I finally found the problem! annnddd have absolutely no idea how to solve it haha. So this afternoon I ran out of unsheilded consumables, more in the mail that will be here later this week, but I had a file I needed to get done so on a whim I tried putting a shielded consumable tip into the unshielded tip holder. Ran the file and it cut beautifully, ok well thats weird. So I remade the file, compensated for the height of the shield and ran it again with the full shielded setup on. Just like clockwork the cut made it about 5 inches and then stopped fully piecing the material, but I noticed something very strange with my thc feedback. Typically in 3/16 steel I will have a running voltage of 112 to 115 volts, voltage with the shielded it was running 15… So i turned off smart voltage and ran it again targeting a nominal voltage of 15 and the cut came out great. Full federate and not a single problem. So what gives? @mechanic416 not sure if this is something you have seen happen before but you may have some insight on it? Really glad I finally found the problem but its definitely a strange one.

You are loosing your voltage reading for some reason. Also may I ask way you bought 60 amp consumables when you only have a 50 amp plasma cutter?