Our shop has been utilizing the Crossfire Pro with TCH in conjunction with the Hypertherm Powermax 45. Parts in smaller batches (1-4) usually have satisfactory results, but when a larger batch is being cut, the parts tend to be partially cut. The Z axis seems to grow mid-cut, and the cut is characteristic of an ungrounded part. I’ve messed with the limits for z axis and measured the actual Z axis height, and it checks out. What am I missing?

Welcome to The forum.

I don’t want to assume anything so what is the current condition of your consumables?

ISTM, you should ALWAYS cut the pieces furtherest from the Work Clamp FIRST. Otherwise you leave a very small current path for the last cuts.

I have had the same issue with new and used consumables.

First are you using REAL Hypertherm consumables? The picture shows the CNC shield and cutting tip is bad.

Yes, these are authentic Hypertherm consumables. The mech consumables are a one-piece design. This issue I’m having seems to foul the consumables because of the spatter being produced due to the incomplete cuts. The cut height is increasing on various parts, sometimes up to 1.5”

You said it was a powermax 45 not a xp or sync., this information would have helped. First thing is to clean and lube your Z axes and check your IHS to make sure its working properly. Use anti splatter on the CNC shield part.

That consumable is long done.

are you running these sync cartridges on a original powerMax 45 with an adapter?

Or are you running a powermax 45 XP with an adapter ?

or are you running a powermax sync 45?

Are you using fine cut mechanized SYNC consumables or standard mechanized SYNC 45 amp consumables

Can you upload a code from one of the larger batches? Do you have separate code for the smaller and larger batches or are you running the small batch code over and over again to make a larger batch?

do you have limit switches on this pro?

what is the actual measured height? And it checks out to the cut chart or to what you’ve programmed it to be at?

Are you using nominal voltage or are you using smart voltage for the THC?

another question to see where we’re your are at is what material thickness are you cutting?

-

The Powermax 45 has a CPC port that I installed so we can use a mech torch. The consumables are the standard 45amp mech cartridges.

-

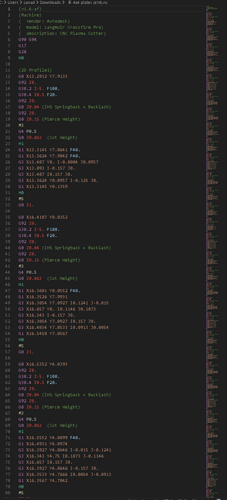

For large batches of parts I have all the parts on one NC File. The file attaches corresponds to the photo of the Miscut.

4x4 plates (x14).nc (30.6 KB)

-

There are no limit switches on the table.

-

When im cutting .25” plate the desired cut height is .15”. It checks out to .20-.25 in reality

-

The THC uses smart voltage

This instance was .25” Plate

in your program you’ve asked the cut height to be .063

and you want it to be 150% of that of that .15

but it’s actually cutting at 200 to 250% of what its programmed to be?

These consumables you’re currently using are already cooked but running a high standoff cutting height will cook consumables fast.

I’ll attach a snippet of the code for everyone else who’s following along.

and are you using the raw connections or the divided voltage connections in that CPC port?

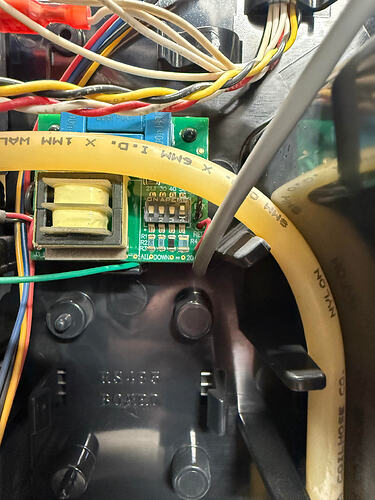

You verified that the CNC circuit board inside the power Max 45 has been dip switched to 50 to 1 voltage dividing if you’re using the divided voltage?

what is the voltage running at during the cut?

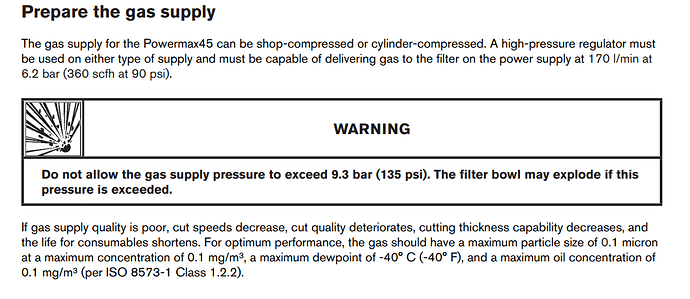

And being that it works on a shorter cut and doesn’t work on a longer cut have you verified that you don’t have too much pressure drop and are starving the machine for air?

Are you running your setup off a generator or a long extension cord?

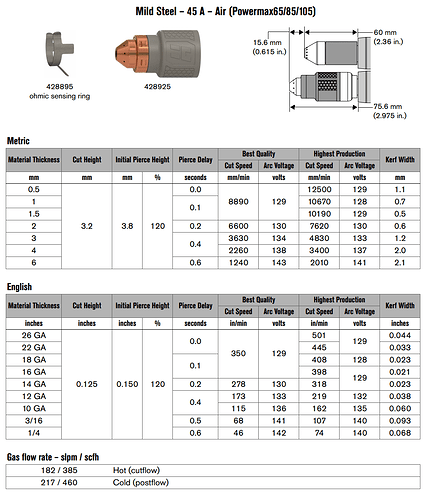

I was referencing the hand-cut consumable chart, and that’s where that .06 came from. I’ve adjusted to the mech cart recommendation of .125” cut height.

The CPC is using a divided-voltage connection, and the switch is in the desired 50:1 position.

The voltage while cutting a part that doesn’t get affected by the issue is 124-130V. When it gets haywire, the voltage can get as high as 150v. The machine is running on good outlet power: 220v, 60 amp breaker, with 6ga wire. I have plenty of air pressure and have it regulated at 80 PSI at the machine.

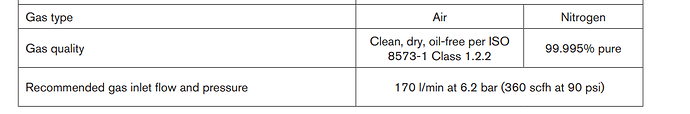

I may be wrong here but the 124-130 volt reading is high for 50 to 1. Also up the air to the plasma cutter to 100 to 120 psi.

+1

here’s from the power Max 45 manual

80 is the bare minimum input

here’s a clip from the cutting chart for the adapter guide

https://forum.langmuirsystems.com/uploads/short-url/1L4jCWETE1H7QARrfgyXX1vP8Bb.pdf

I still don’t think those voltage reading are for 50 to 1. They seem more like raw voltage readings.

I’m pretty sure he’s talking about what voltage he’s seeing in fire control.

The plasma torch is putting out 50 to 1 to the vim. The vim is taking that 50 to 1 signal and augmenting it into a 73 to 1 ratio then fire control takes voltage and applies 1 to 73 to it to display it.

He’s probably two to three volts at the plasma cutter. If he were to take a direct measurement there.

Good morning, I applied everything that was shared above on a new batch of parts, and the problem persists. One part went perfectly, then on the second part, the Z began to rise, creating an incomplete cut.