Ground up Walmart brand rattle can…

I was talking about the Columbia Coatings powders, but Prismatic will be in my inventory sooner than later. I’ve heard good things about their translucents and I’d like to try that out. @SWomack are you saying Prismatic paint is not good? I’ve only heard good things so far, what’s your experience with them been?

https://www.columbiacoatings.com/resources

weird that the links are broken to their SDS and TDS.

SDS are supposed to Publicly available and quickly accessible. ![]()

i have sprayed a lot of prismatic powder and still do with great success . For unknown reasons i still strongly lean towards Columbia coatings powder.

ive got a ton of colors from prismatic, all of them ive been plenty happy with and their shipping is pretty fast at least to my house, order on a monday and have it in hand on wednesday

I just built my oven this year 3x3x6, 2 3000W elements

Looks great! More pics!

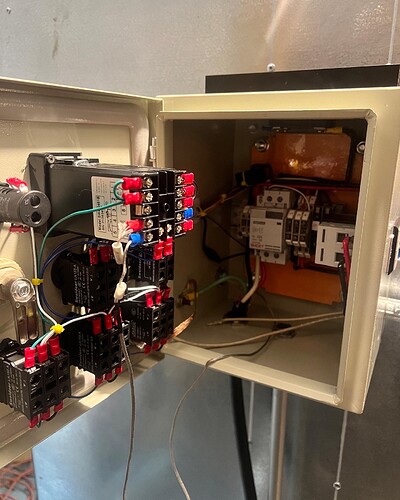

Unfortunately don’t have many pics from building it but here’s a couple I did take. I mostly just made it up as I went. The control panel is the pre-built from Auber, everything is 20GA Galvanized, except the floor is 16G steel. It’s a huge step up from my original oven:

Man that looks great! The switch for the alarm is a great idea, drives me nuts having to hit reset every ten minutes…ROFL. Maybe I should just put a switch on my timer. I was going to ask if that was the Auber panel, they have the nice clean knockouts. I like that VA Meter too, I was on the fence about which one to get. Nice oven!

Yea the box is really well built, I almost bought their listing on Amazon but then realized it’s much cheaper directly on their site. If you need any info on the reset switch or whatever I can grab it for you.

I just added 6 magnetic little timers and magnetic dry erase index cards to the side of the oven so I can time individual pieces as I go which has been helpful.

Also for getting cure times perfect I bought an alligator clip K-type thermocouple and a digital thermocouple meter. This way when I outgas I can clip on and see exactly how long it takes the part to get to cure temp. I mostly do 16G so I don’t have to use it often but anytime I’m doing something besides 16G I can figure it out really quickly

Im curious have you ever compared your temp gun reading to your Clip on T/C?

I got the clip on because my temp gun was giving me poor readings due to the reflectivity (that a word?) of the metal. First tried a cheapo gun and it was wrong, then bought a Milwaukee temp gun which was still wrong, then got the clip on TC which is dead on accurate. Oh and also I can use the clip on without ever opening the door, I just clip it on, close the door, watch the meter.

After I have powder on the parts the temp gun will work perfectly but on my bare, prepped metal the numbers were far off. Although I swear the guns a bit off on super glossy coats but I’m not clipping onto it’s surface to check lol

There are guns that supposedly can compensate for the “reflectivity” of certain metals, but I never tried one. I think Dewalt makes one, I remember it being yellow I think

I have a older Fluke that has maybe 8 different settings but it sometimes acts up and they wont repair it.

pretty sad being it was like $800 new.

How did you test it once powder was on to know it was reading correctly?

To test it I put a part coated in a matte finish that’s already cured in the oven and an identical part still bare metal in the oven. Clip on the bare one

The gun can’t read the bare one accurately but reads coated one, and it matches the clip on temp of the bare one.

I could probably clip on a cured one without leaving marks to be 100% sure but don’t think I’ve ever tried, checking the temp after cure I only really do when I need to handle it right away which isn’t too often

Surprised Fluke won’t help you out, I’ve always heard they’re good about it, I have their 88V and love it. But for this thermocouple I just have a cheap setup it’s a Proster meter that was prob ~$25 and I forget the thermocouple brand but it was like $15? The meter is a 2 channel and all it does is output thermocouple readings and nothing else so less of a meter more of a display

I would think your way of checking is as close as you could ever come. I wonder what powder coat manufactures use to check temps when there designing powders.

I’d imagine they’re determining their temps based on the compounds used in the powder, cure temp is just when the cross linking of the fluidized powder occurs so I’m sure they can determine that in a basic lab setting. But that’s just a guess all I know is “spray clouds, make pretty”

Really good info there Teknic, where the hell were you when I was building my oven…I’m 100% going to look into that alligator clip TC and display. I thought I was having issues with my gun too when my original TC wasn’t reading right, so I bought a second gun and the two guns were within 1% of eachother. That’s when I ordered the new TC.

Good news, the new sign project is finished so I’ll get that video edited this weekend. It’s by far the nicest thing I’ve made so far and probably the biggest. 31" round sign, 1" deep with a backing plate, remote control lighting and way too much acryllic sheets. Here is a pic from middle-ish of the build.

This was taken right after I finished rolling the ring and welding it on. It’s a gift for a family member. All done it weighs about 30 pounds I think.

That is a heavy sign!! It is looking awesome! I am about to begin an 8ftx8ft with 5 different colors of acrylic and led backlighting tomorrow.

Make sure to document that build.

I’m editing the video today, I think I have just about all of the process on video from cutting to bending to welding to painting to cutting and shaping the acryllic to the backlighting. It should be a cool video, it turned out pretty good. If I don’t post the video today I’ll post it tomorrow, I don’t want to post it until I give it to my fellow Hawks fan in the family!