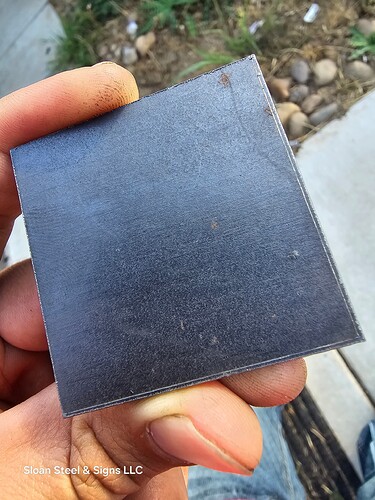

So im trying to use an easyscriber to scribe stud locations for welding on a sign. The scribe marks are off by a 1/16" in X and Y it seems. Anyone have an ideas what could be causing this and a possible fix. I cut a circle and a square for tests and theyre similarly off. The sign has about 20 studs spanning 35ft, so this could cause a problem for the installer i would imagine.

If you turn the scribe portion 180 degrees and do a test run. If it is off in the exact opposite direction then I would guess that it was not machined properly.

I see there is a spring-loaded component to that EasyScriber. Is there any lateral movement when It moves up and down?

Is there a lead in or pierce clearance somewhere in your file?

I had to cut some holes in a piece of bar stock and the cut file had a perimeter cut to help line up the torch with the work piece. I wasn’t using the perimeter cut, but the lead in on the corner, caused my holes to be off by the length of the lead in. This was because Firecontrol moved the origin over to align with the lead in start point.

No lateral movement on the scribe. I made the file with no lead in or lead out and no pierce clearance snd offset to center

Is your part coming out the right size? I wonder if your kerf is programmed accurately enough.