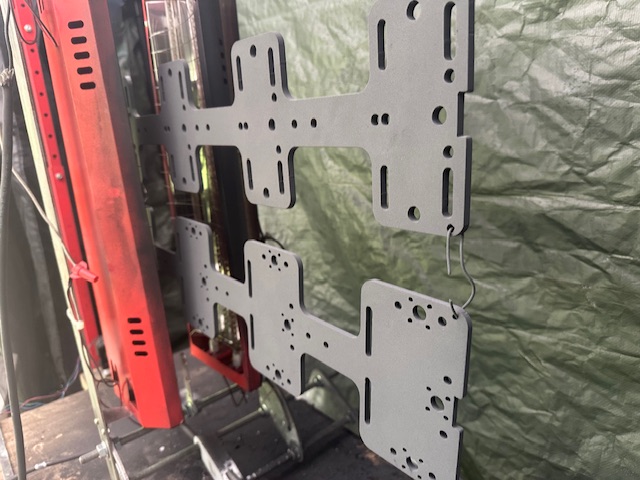

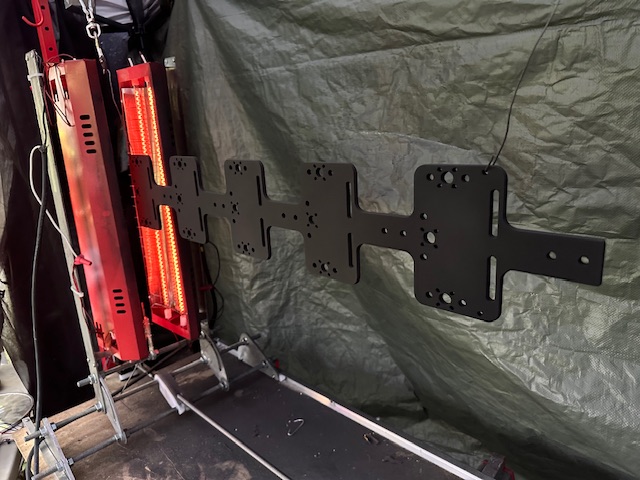

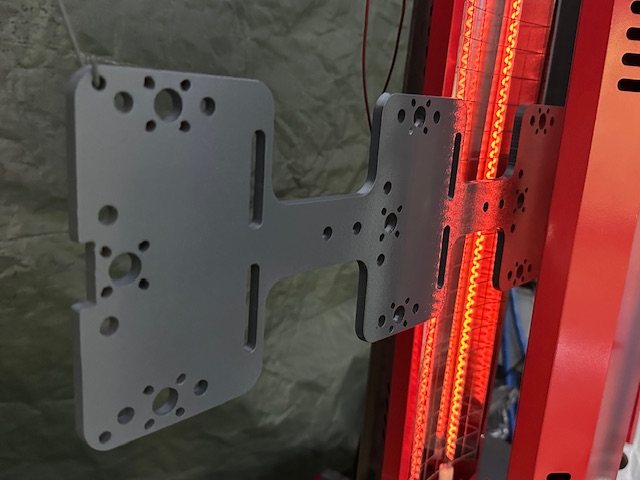

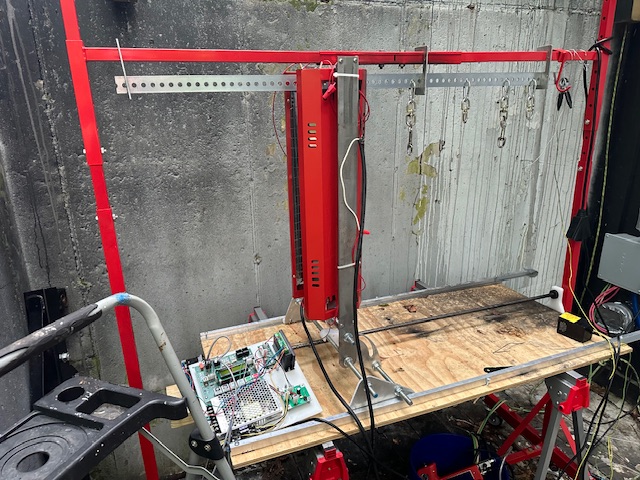

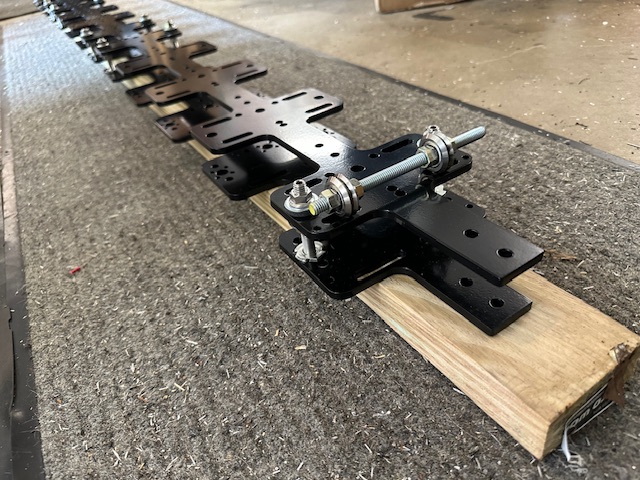

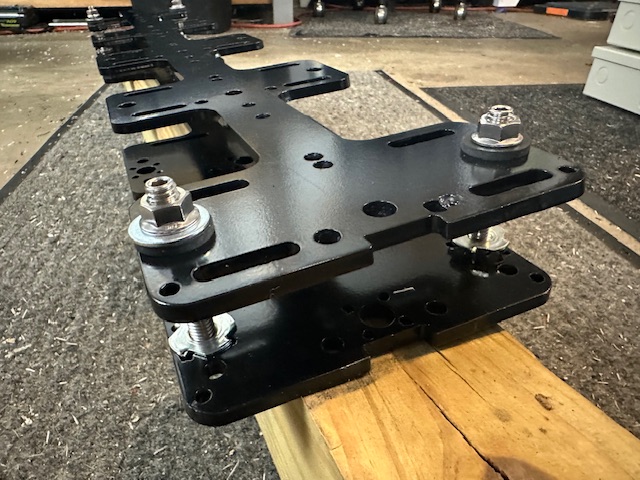

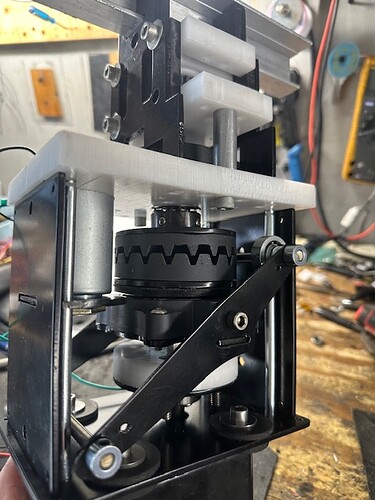

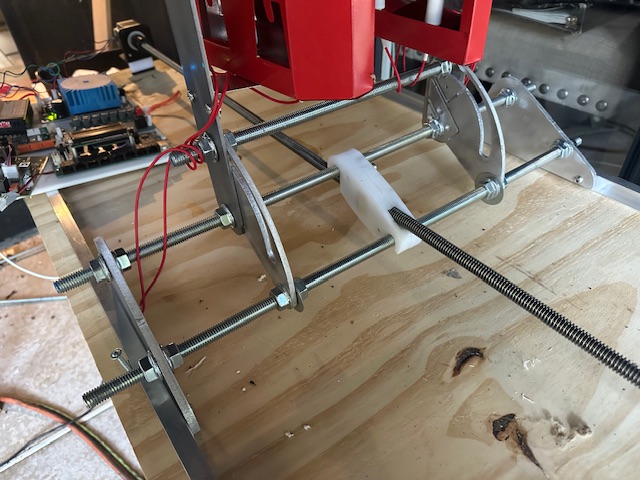

I needed to powder coat some stuff and lead times were too long at local places. Plus some parts are prototypes and would require updates I didn’t want to buy a large oven minimum 2x2x6 to do this project. So I experimented with some infrared lamps and tested and came up with some duty cycle rates (on time versus off time) for the lamps to maintain a temperature at the metal surface. I built a controller and mounted the lamps on a track system with a motor. Added a menu to allow any rate of speed of the lamps and defined travel length. For example. Lamps are 6” wide. My powder wants 10 minutes at 400f. I set the speed to .6 IPM and tell the lamps to move a certain distance in inches to cover the part to bake . This makes the lamps put 400f on the surface for 10 minutes while moving down the line. This track is 48” but can be anything. A belt driven version ( next revision ) can be any length.

I hang the parts on the track at top. Shoot it. Press run and the lamps move over the surface For the predefined distance and rate of speed and duty cycle (temp).

This is working out really well for my project so I thought I show the system.