I am able to cut longer peices because the stepper motor cord is too short to allow it to clear the over-hang of the piece. Anyone know wha tto do here? I was able to do it on one smaller piece by removing the cord and threading through in opening in my work… am I missign something?

James,

I might be completely wrong here but, it sounds like you are “sliding” your work along the X-axis of the table thus having your material run under the Y-axis rail when you do your indexing…

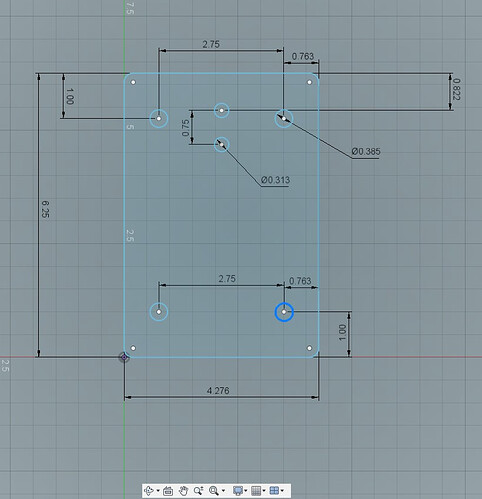

Are you able to rotate your drawing in Mach3 and do the “sliding” along the Y-axis of the table? This way your workpiece shouldn’t interfere with stepper motor cables??

Maybe attach a picture if you can. And, I could easily be picturing this all wrong. If so, just humor me… LOL

Yes , it is more comfortable in my translation to do along the x - I didnt want to move my whole layout to the y… i have all the code generated it not like a rabbit doing that. and i am out time to get this work finished and shipped for christmas. Can i just swap the motor ports - and effectively rotate the table to yx instead of xy

The other reason its more comfortable to do the indexing along x is because it is perpendicular to the slats which i can clamp my fence for indexing… if I rotate it to y… I have nothing to clamp my fence to except a single edge of one slat… see where it gets more and more convoluted.

Yes, I understand what you are saying for sure… You especially sold me on the clamping the fence part. I can see where running like that is an advantage…

Not sure about moving ports as I’ve never tried that…

Please let us know if you gave this a shot… Sounds like it should work though…

Pretty sure you can rotate the drawing on the table in Mach3 though…

I know this doesn’t help you with your fence… Maybe clamping your fence down between slats using a piece of angle iron??

The real kicker is i opted for the 33 xl upgrade - hoping to do a 33 x infinity instead of 24 x infinity… but if you cant set the infinity in the x direction… you will just have 24x33 table that is capable of 24 infinity. and you never get to get the 33 x infinity… you see where the real deal of what i want to do is now//?

Yes, i am going with the rotate ports for now… but ultimately i need switch the axis to 33x infinity.

Yup… Makes perfect sense now… So, rewiring the servo motors with longer cables would be the end of it… Doesn’t help right away but, could be an option for the future…

you can get an extension cable. i believe its a DB9 (serial) port male to female cable.

When i worked without the water table, I could slide the stock under the Y carriage. The water table moves the slates too high, even if you were to size them no naught with the edge of the water pan. I need to fabricate a stanchion plate with about extra 1/2 inch rise… then I will be good to go with a longer cable.

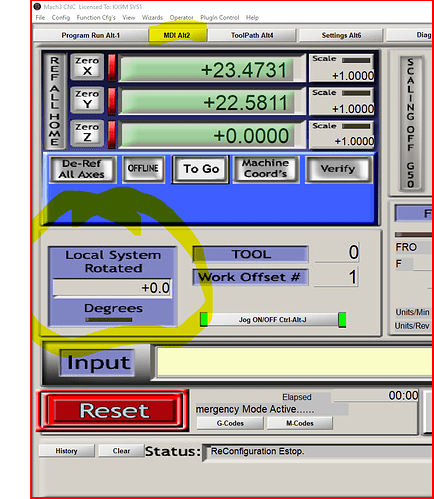

Without some pictures, this whole thing sounds silly… But… You can do a few things… The user above show the rotate screen in mach3, click in there and type 90, or -90… now x is y, and y is x… Or you could just swap the serial cables on the x and y motors where they plug into the langmuir box… Not sure if you would have to change the motor directions in the ports and pins configuration… Or, open up the lanmuir box and swap the plugs on the motor controllers inside the box, the ones that go from the break out board to the motor controller.

I have yet to build my Crossfire (too many Holiday projects to finish first!), but I plan to move the Y motor to the opposite end of the axis and move the controller box to that opposite leg. Looking at your indexing issue, I notice that, by moving the Controller box to the opposite side, the X lead will be able to be routed over a nylon pulley (maybe mounted on the Y rail riser plate) to keep the cable out of the path of any workpiece that is extended under the Y rail. All you would need is a small weight on the X lead to keep enough tension so the lead stays in the pulley and doesn’t sag into the path of the workpiece. I’ll post photos when I finally get this built but this change seems useful to me as well.

Now that I’ve gotten my CrossFire as far as running the break-in program, I realize the folly of my suggestion. I hadn’t expected the X Motor cable to be as short as it is and, not only is it not able to be routed over my suggested Nylon Pulley, it won’t even reach the X Motor connector over the full travel of Y when the enclosure is moved to the opposite leg!

Clearly the cable needs to be lengthened in my case and, it seems, would need to be lengthened in OP’s case as well. Good thing I know how to drive a soldering iron! ![]()

It’s a standard cable with DB9 connectors. You can get extension cables on Amazon.

Is the current capacity sufficient?

I am going to flip the axis on this and cut new stanchions about a 1/2 inch higher. then i am good at 33 x infinity. I will add a longer cord and add a support for the cabling.

Just cut taller stanchion plates for my table here as well… Ordering longer cables and coming up with support for them… This does seem like the best way to go… On to 33"

x Infinity as well…Good deal. Thanks, I will update after I have chance to make the upgrade as well