Unfortunately 1/8" is pushing the capability of a fine cut package. A 40a set up is what i would use. Personally i would use fine cut for anything 14ga. And lighter, regardless of marketing and popular cut charts. You really want to fall in the center of those cut chart variables for optimum cuts. You can push them, but the results are going to push too.

So here you said it was inconsistent, is this still the case? Normally once your consumables fail they are done, they dont start working again.

I did tighten the Z axis rollers. Also the THC settings I was running were not book settings. I went back to the book settings and it has extended the life of the cartridge. I’ve noticed they continue to work but the bevels get really bad and inconsistent to the extent I swap it out. If I’m cutting 18G or 16G its possible they can still be used because bevels are not really noticeable.

I agree. I cut parts that have a bunch of 1/4" wide slots that are pretty long and I don’t think I can get the quality I want with a 45amp cartridge. I started having these parts laser cut now, saves me time and frustration.

I have started using 45amp cartridges on bigger 1/8" parts I sell and it was nice to cut 50 of them and see very consistent parts.

I cut 1/4" with a RW45 at 45 amps and have very little bevel. Remember your always going to have some

Agree totally with you Knick.

Two weeks ago I cut these 1/4 inch thick target blanks with standard consumables on my Hypertherm 45 XP. The consumables probably have 500 pierces on them.

These pictures show the metal just off the table. No effort was made for any dross removal.

You will notice some nicks in the discs due to a very small lead-in, but the targets will not look pretty after the first few shots.

Oh I hope you’re putting those targets up at 200, 300 and 400 yards respectively.

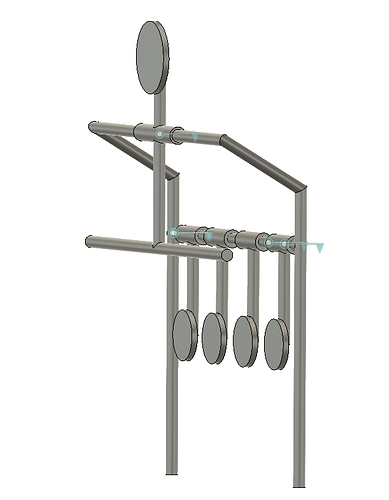

Nope. It is for pistols (22’s) for this contraption.

Last time we were shooting about 40 feet away at 1 inch discs. I scaled it up so we could have a little more success.

The original design was for rifles.

The large disc was for the “reset” target, not for the competition targets.

But it is funny you should say what you said. One of the guys that was with us (a few weeks ago) said exactly what you said. He tried to hit those one inch discs and only hit 2 or 3 out of 15 shots.

If I recall correctly, when in the Army, the pistol qualification was 25 M (~75 Ft). It seems the center mass of the target was ~ 2in in diameter, so 1in at 40 Ft is reasonable.