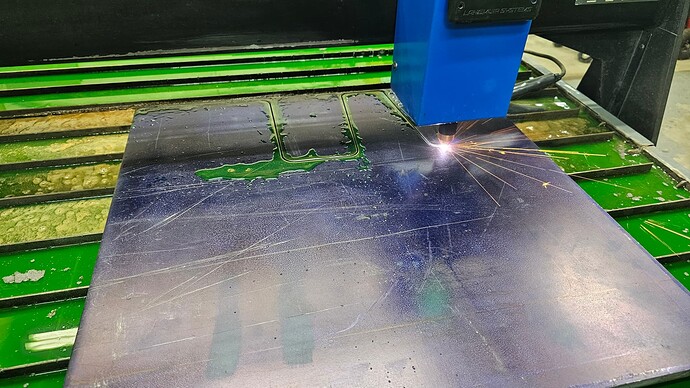

Hypertherm’s new 65 sync is a thing of beauty cutting 1/2 plate. WOW!!

New client ordered a bunch of pieces and future orders cut from 1/2 plate. The Cut60 wasn’t going to cut it. So I bit the bullet and upgraded. I ordered a 65 sync a few years ago but cancelled the order when a previous customer backed out on a big job.

Making 5’ 6’ 7’ and 8ft totem poles out of 1/2 plate. Looks like an XR is next. Indexing 4’x8’ 1/2 plate suuucks!

LOL! I saw your work and thought, gee that looks ‘cute’… until I read that it was 1/2" plate! Holy $hit! I’m not sure I could lift the finished piece!

That’s a testimony for the Hypertherm for sure!

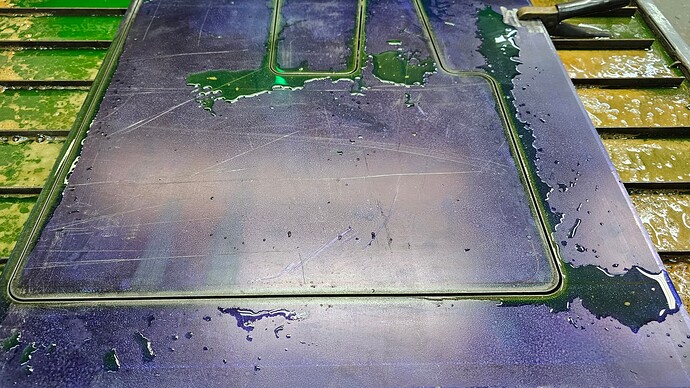

1/2" mild steel cut on my XR table with Hypertherm powermax 45 XP cutter. No grinding, customer couldn’t believe quality of cuts and accuracy.

Hi there, I know this is an old thread, so I hope you don’t mind me jumping on it. I see you are using the Hyp. sync version. I’m contemplating the same machine, only the 45sync, but was wondering if you have had any trouble with the cartridges getting damaged by the water in the table. Worried about the electronics in the cartridge. Would you mind letting me know your experience.

Thank you.

I am using the Hypertherm powermax 45 XP plasma cutter, It is NON- SYNC machine.

I don’t think that water is an issue for a Sync machine cartridge, there are others on this forum that use the sync, they can chime in to let you know.

Great to see you considering the Powermax45 SYNC! The electronics inside the cartridges are extremely well-protected.

Thanks for the reply, I have really been scratching my head over this subject. So how long have you been using your sync version cutter? Are you finding that not much water hits it in the first place?

Hoping for the official word, I contacted Hypertherm directly, and after a lengthy phone conversation the fellow continually repeated that the torches were not designed to be run over a water table, they were designed to be run on a downdraft system, and that if water did get into the cartridge, it WILL cause problems.

So…I was just wondering, from your personal experience, what can you tell me?

Thank you very much,

Craig.

I have had the 105A sync version for over a year now, maybe even 2, never had a issue with water. I don’t cut submerged or intentionally dunk the head, just normal stuff from 3/4” steel down to 1/8” steel. The only time you get any major splashing is at the end of the program when the torch stays in the same spot until the post air stops. I just get ready to move it once the program is done, not to protect the torch, more to stop water splashing over the side of the table.

Never once in 2 years have I had any water issues, at least not that I know of. I do replace the cartridges quite a lot.

When I have a $1,000 plus plate on the table and I have the entire 8x4 sheet nested, the price of a new cartridge is insignificant. So I install a new and save the old for another time.

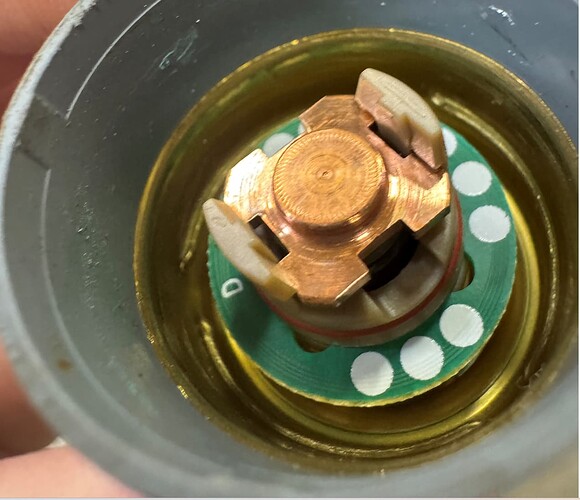

Thank you, this is the kind of real experience information I have been seeking, not just opinion. As mentioned, I am contemplating a sync unit but have never even had the opportunity to look down inside the cartridge itself. Can you see the electronic components or are they somewhat covered? After changing out a cartridge have you ever noticed water droplets on the inside, or anything that might look like powdery residue from whatever additive you use in your water table? Thinking of corrosive action on the components.

For reducing the possibility of water getting in thru capillary action down the threads, all the Hypertherm guy could suggest was a wrap or two of black tape around the seam.

I’ve never noticed anything unusual to indicate any kind of water ingress. Here is some pics of inside a used cartridge. On the torch itself, there is an O-ring on the threaded part this cartridge screws onto.

Since this subject is still going on.

Good friend of mine put over a year and a half of continuous use on his 65Sync.

I’m talking 7 to 8 hours per day, 5 to 6 days a week, for that entire year and a half.

Cartridges would be soaked as he ran a lot of fluid cutting lots of 16 gauge on his 5’ x 10’ table.

These machines are not delicate, and many people go as far as performing submerged cutting. Would I do it? No. But you’re not going to ruin anything by getting the cartridge wet like you’ve asked multiple times.

He’s not running it anymore as he bought two CNC laser tables. That’s how often he ran his 65Sync that he upgraded to such tables.

Thanks for the reply Craig1.

It is funny though that you say there is an “O” ring there. I specifically asked the Hypertherm guy if there was any “O” ring seal there, and he said no.

Maybe he was referring to the 45 which I was asking him about at the time.

Thanks again for all your help, it goes a long way in helping me make up my mind.

No problems with water and the electronics in cartridge.