Yes I did.https://longezproject.blogspot.com/2019/01/tooling-up-cnc-plasma-cutter-update-3.html

Thank you for the write up! I follewed it exactly but the machine still wont fire except when using a non modified hand torch and doing it by hand. Getting continuity on the CF output and have it plugged in ports 3&4, and machine has no faults(brand new 45xp w/CPC). Any help is appreciated

Never mind… I figured it out. For some reason I had to release the trigger and pull(ziptie) it again.

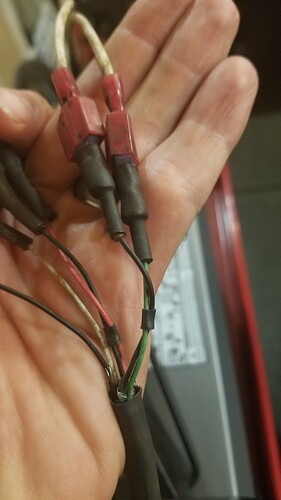

Hey man, was curious if you got Hypertherm 45xp with Machine torch wired up to the cable that came with the Langmuir? Just got mine in with the machine interface cable part# 023206 ( mine has 4 spade connectors with 2 black wires and a green and a red).

Most of this discussion envolves the hand torch and was hoping to get some help on wiring up the machine torch.

Any help would be greatly appreciated. Thanks

Yes I did! I’ll snap a pic of the two ends spliced together when I get home.

That would be great. Email jp062976@gmail.com. If needed. Thanks

Thanks! You’ll have to excuse me for dumb questions because I’m completely ignorant when it comes to anything electrical. How do you determine which black wire to use? My interface cable has 4 spade connectors not the 6 I think yours is showing. So I have two black one red and one green. Does it even matter which black I use? Thanks again…would love to get this up and cutting.

Just thought I would comment on this topic: Hypertherm has safety interlocks built into their systems so that users can safely plug in a hand torch for hand cutting (with activation via the trigger switch) and then unplug it and plug in a machine torch (mounted on a cnc machine, a pipe cutter, a track burner, etc.) for mechanized cutting with a remote start input. This interlock ensures that a hand torch does not accidentally fire from a remote trigger. There was a lawsuit a few years back where a user of both hand an mechanized torches accidentally triggered a hand torch that was neatly stored by wrapping it and hanging it on a high pressure acetylene cylinder. The torch fired, puncturing the cylinder and the whole shop burned to the ground…no one was badly injured. The ensuing lawsuit cost Hypertherm a lot of money, the interlock has been on all systems since, bypassing the interlock will void the warranty. Use a machine torch for machine cutting, start signal through the CPC interface port, use a hand torch for hand cutting with the start signal activated with the onboard trigger switch for best results and safe operation. If you modify any internal wiring and you need to get warranty repairs done on a Hypertherm…make sure any wiring is returned back to original before sending the unit to a repair facility. Jim Colt

I just purchased powermax 45 xp from local Praxair dealer. Machine torch with cpc port. will use exclusively on Langmuir table. Expect delivery 1 + week due to holiday. How do I wire Langmuir cable to cpc port. I do not want to touch interior or new machine. I know there are 2 wires from the Langmuir controller that will go into a connector to connect to the cpc port. Are there any diagrams for this operation and do I need to purchase the Male port connector?

The two plasma start wires from the Langmuir connect to pins 3 and 4 on the 45XP, they are not polarity dependent. In the installation section of your Powermax operators manual there is a pinout diagram of the CPC plug. The other two signals on that CPC port are: 1. The arc transferred signal (this indicates to the machine the exact momemt that the arc start cutting metal before each cut cycle, I don’t believe this is used on the Langmuir machine) , pins 12 and 14, contact closure when cutting, open when arc is not transferred) . 2. Divided arc voltage (this is cutting voltage feedback for cnc machines that have height control). Jim Colt

This was just what I was looking for. I remember talking to @jimcolt years ago when I was getting started with my cheap harbor freight cutter. Now I’m getting ready to order a Powermax45 to run on the Crossfire Pro! I won’t be needing to switch back and forth from hand cutting to machine cutting. I’ll just use my beat up harbor freight for random hand cutting.

I just made my order to lock in the April delivery. I’m trying to figure out if it’s better to use a machine torch vs. a hand torch and a few other things. I’m hoping to get my Powermax in the next month and have it ready to go. I’ve got to say it’s pretty awesome to see @jimcolt still on forums and helping out customers.

Order your Powermax with a machine torch, it will be well worth it.

Holy crap I remember you from welding web years ago too!

I ordered mine with a machine torch and no regrets. Also use old harbor freight unit for misc. hand cutting

Alrighty. I’m experiencing now what I refer to as research overload. Not sure what exact model to go with. So far it appears that model number 088121 is exactly what I need. From there I just need to buy a new cpc connector to adapt the Hypertherm machine torch pins to the proper pinout on the Crossfire Pro? I’m also going with the height control, does that change the type of machine torch or cpc configuration?

don’t think so. You will have to add 2 more wires to plug for THC as I understand it. Will be doing same when THC available for xl people.

That makes sense. Reading about how the THC works it needs to know the voltage at all times.

Is cut quality the same when using machine torch vs. 15 degree torch modified?

regards

Assuming the torch is perpendicular to the material there will be no difference in cut quality. Be sure to use the consumables designed for mechanized cutting and follow the cut chart specs for mechanized cutting from the operators manual. Jim Colt